The corrosion of steel piping and its related components is a continuous and virtually unstoppable process. The end product, which is commonly referred to as rust, is simply the result of an electrochemical reaction through which the higher energy-processed metal is slowly reverted back to its naturally occurring form: metal ore.

Even with the proper application of available countermeasures, the estimated cost for replacing corroded piping systems in the United States alone stands well in excess of $75 billion annually—making corrosion one of the most potentially damaging losses to any commercial, private or industrial property.

The financial impact of all metal corrosion on a worldwide scale is staggering—resulting in losses of $1 trillion in the United States alone for 2012. (Review the latest cost of corrosion statistics.) And according to a NACE conference paper, each year in the United States hundreds of millions of dollars are spent to replace steel pipe that have corroded and failed.

Over $121 billion is spent annually in the United States on corrosion control chemicals, coatings, and other protective systems. (See An Intro to Pipeline Corrosion and Coatings for more information.) Hundreds of millions more are spent on corrosion monitoring and testing.

An estimated one-sixth of all steel production worldwide is used to replace corroded metal—much of it at cooling water piping systems. And yet, corrosion problems are increasing in frequency and severity, not decreasing.

Fire protection systems now fail within 2–3 years. Entire condenser water and cooling systems fail within 5–10 years. For various reasons ranging from declining material quality and engineering (read Decline in Quality of Piping Making Corrosion Inevitable) to less effective corrosion controls, corrosion activity now presents to many property managers potentially career-altering challenges.

Problems Mild to Severe

Next to fire, pipeline corrosion represents the most serious threat and monetary loss to any commercial or industrial building, or plant operation. In its less serious form, corrosion can produce problems ranging from lost heat transfer efficiency and constricted pipes to annoyance pinhole leaks and temporary shutdowns.

More serious failures are often in the form of million-dollar flood damages, operating failures, lost production, productivity interruption and personal injury. Potentially worse consequences exist for fire protection systems where there is an internal corrosion problem, because the volume of iron rust deposits generated has the potential to clog the pipe and thereby render the fire protection system totally worthless.

In extreme yet all too common examples, the failure to recognize a serious corrosion problem will result in the need to replace some or all of the piping system at an extraordinary cost, and possibly with the loss of life and critical services.

Multiple Reasons for Problems

Finding oneself in such a position, however, is not an overnight event. Most high-corrosion scenarios result from years of problem conditions that have gone unrecognized, unaddressed or ignored. Often, it is inherited from a previous owner or operator who was not effective at controlling a corrosion problem, and/or was obviously not concerned.

For many of the worst corrosion problems we have been called in to investigate, a total reliance and blind trust in corrosion coupons have allowed years of sky-high corrosion to continue unabated.

Through our involvement in the field of chemical water treatment and ultrasonic pipe testing since 1981, we have seen a surprisingly high number of facility engineers and plant managers interested in extending the retirement date of plant piping just slightly beyond their own! A fact rarely obvious until a major and often premature failure occurs.

A combination of less effective corrosion control chemicals, lower quality and less corrosion-resistant metals, and less tolerant design engineering practices have made the need to closely monitor corrosion losses more critical today than ever before.

Documented Examples of Pipe Corrosion and Failure

CorrView International, LLC offers a series of photo galleries taken from 18 years of past ultrasonic piping investigations, which address the above and additional corrosion conditions. A review of the different types of corrosion is often helpful in initially determining the likely corrosion cause.

In many cases, however, a combination of conditions will exist within the same piping system.

Here's a look at 21 different corrosion types and failure conditions.

1. Piping Failures

A piping failure is often the first sign of a corrosion problem. Yet in many examples, signs of an impending pipe failure have been evident for months or years, and gone ignored. Failures can be minor (in the form of a pinhole leak) or catastrophic, with significant losses due to water damage as well as the cost of pipe replacement.

2. Pipe Repairs

Pipe repairs take on various forms, ranging from temporary clamps to the replacement of entire piping systems. In many examples, the denial of a corrosion problem results in multiple or staged repairs over years, wasting valuable time that could have otherwise been used to correct the problem and minimize far greater corrosion damage. All too often, one or multiple individual failures are fixed without further investigation into the hidden cause.

The absolute reliance on favorable but typically inaccurate corrosion rate data presented by corrosion coupons, often in contrast to blatantly obvious physical indicators such as thread leaks and high rust deposits, allows a high corrosion condition to continue unabated, thereby producing a much greater repair problem once the true corrosion problem is finally realized.

.

.

3. Pipe Thread Leaks

Every pipe thread is an inherent point of weakness, with approximately 50% of the pipe wall cut away. Often, a thread leak is the very first sign of a corrosion problem and will prompt further investigation. Left to continue unaddressed, however, total pipe separation often occurs to produce devastating water-related damages.

While the condition of large piping mains is normally the greatest concern to a building or plant manager, it is the threaded pipe that typically causes the greatest damage.

A high pitting condition will cause failures at random areas of the threads, allowing water to pass through, even though sufficient pipe wall remains to prevent a larger failure. For small leaks where the rate of evaporation exceeds water loss, dissolved iron oxide and other deposits accumulate at the threads to suggest a corrosion problem originating at its outside surface. In reality, however, it is an internal corrosion problem.

For more uniform but high corrosion activity, a more dangerous condition exists at the threads since the pipe wall is reduced more evenly and does not provide the telltale leak indication of a problem. For all forms of thread leaks, the potential always exists to suffer a total thread failure.

4. Galvanic Induced Failure

Galvanic corrosion can occur when different metals are joined together, and is greatly dependent on already existing corrosion conditions and the piping system involved. It is more common in open condenser water and process water systems than in chill water or fire protection systems, for example. It commonly occurs between a carbon steel pipe joined to a brass valve, with the most serious examples found at galvanized steel to brass valve connections. (Learn how to avoid galvanic corrosion.)

A bluish-green deposit at the valve and lack of leakage at its opposite steel-to-steel connection provides confirmation that a galvanic condition exists. It is most prevalent where corrosion activity is already high, and can produce widespread failures and total pipe separations.

In many cases, a leak at a thread between black steel pipe and a brass valve or copper pipe is automatically assumed to be due to galvanic activity when a much larger and more threatening high corrosion problem is actually the cause. In such cases, pipe replacement with dielectric insulating fittings is a costly misdiagnosis that can lead to years of continued higher corrosion activity and eventual system failure.

Galvanic corrosion takes place when two dissimilar metals are present along with acidic solutions. This type of environment creates a battery that produces electrical current flow between the metals. To keep this from happening, a dielectric fitting is used, as it also serves as an insulator between two metals, putting a stop to electrolysis.

5. Interior Pipe Deposits

Internal rust deposits, commonly termed tuberculation, are an inevitable death sentence for most piping systems. They are the lighter and less dense end product of steel pipe corrosion. Once established by high and uncontrolled corrosion conditions, internal deposits initiate much greater deep pitting.

The highest corrosion loss is more likely at horizontal lines and in low flow or dead end areas where rust and other deposits will settle, but can affect vertical lines and main risers as well. Random areas of high tuberculation are actually the result of a high pitting or cell corrosion condition directly beneath it, with the volume or height of the rust deposit directly proportionate to the depth and volume of pipe wall loss.

6. Insulation Failure

Contrary to manufacturers' claims, standard fiberglass insulation provides an ineffective moisture barrier for cold water pipes. Condensed area humidity then produces a secondary, and typically hidden, corrosion condition at the pipe exterior. Most common at chill water and dual temperature systems, external corrosion losses will well exceed internal corrosion rates by up to 10 times or more.

Over decades and hidden from view, insulation failure can destroy entire piping systems. In most examples where the insulated pipe is not hidden from view, an insulation failure problem is very easy to recognize.

Missing, damaged, walked on and broken insulation defines a likely problem worth investigating. Water damage, dripping pipe, discoloration or crystallization of the outer insulation surface are further signs suggesting a potential problem. Aluminum and vinyl outer jacketing provides little resistance to moisture migration, but does shield the often telltale discoloration of the below insulation from view. (Related reading: The Role of Metal Jacketing in CUI.)

In addition, vinyl jacketing often holds the water condensed at the cold pipe surface, producing a much greater threat of exterior pipe corrosion.

The threat of insulation failure is greatest in smaller diameter piping due to its inherently lesser wall thickness combined with generally thinner insulation applied. Lower temperatures at supply side piping can significantly increase this threat. (More on this topic is available in Corrosion Under Insulation: The Challenge and Need for Insulation.)

7. Weathering Damage

Of all the forms of corrosion caused to piping systems, weathering damage due to rain, snow, atmospheric conditions or cooling tower overspray is the easiest to prevent. The piping is exposed and accessible, with corrosion activity always visually obvious.

Most weathering damage requires decades to produce a failure, and is simply due to a lack of maintenance. Smaller diameter piping is always most vulnerable due to its inherently lesser wall thickness.

8. Under Deposit Corrosion

Under deposit corrosion represents one of the most damaging forms of corrosion to a piping system. Often called "cell corrosion," it is typically very aggressive and localized, causing deep penetration of the metal surface with lesser general corrosion in the surrounding areas. Due to surface deposits, electrical imbalance, or some other initiating mechanism, all corrosion factors attack a select number of individual sites.

In some cases, pitting is extended throughout the entire metal surface, giving it an irregular or very rough surface profile. In other instances, pits are concentrated in specific areas, leaving the majority of the metal surface in a like-new condition. Galvanized pipe is highly susceptible. Microbiological attack is often associated with under deposit corrosion. Regardless of the underlying reasons for an internal piping deposit condition, the presence of rust deposits signals a multitude of potential problems to varying degrees.

As we have stated repeatedly, under deposit corrosion is an inevitable death sentence to any piping system. Therefore, effectively removing such deposits so that chemical inhibitors can again reduce corrosion losses must always be considered a highest priority.

9. Corrosion Under Insulation

Corrosion under insulation is a widespread and typically hidden threat. The underlying source of the problem is a misconception that fiberglass and/or soft foam insulation provides a moisture barrier, and is the primary choice of insulation based on reducing heat transfer, rather than reducing humidity migration.

Most cold water piping has insufficient insulation thickness, is of the inappropriate type, is improperly installed or all three. Damage, breaks and areas of missing insulation allow the easy migration of moisture.

This is a widespread and very massive problem in apartment and condominium properties where dual temperature heating and cooling risers have been installed at exterior building columns. Now 45 or more years after construction, the riser piping is almost totally destroyed from the outside—with no options available other than total pipe replacement at an enormous cost and inconvenience.

Smaller diameter pipe is more vulnerable to CUI due to the typically lesser insulation thickness applied and inherently thinner pipe wall. Supply side pipe is always impacted worse due to colder surface temperatures.

The addition of threaded ends adds another layer of vulnerability for smaller pipes commonly found at chill water and dual temperature systems.

10. Missing Piping Insulation

Piping insulation is an important and necessary requirement of any mechanical plant operation. While insulation at steam, condensate, and other hot water lines is needed to prevent heat loss, it is even more important to chill water and cold piping services since moisture condensation can severely damage the pipe. It seems illogical, but proper insulation is often overlooked, resulting in potentially significant piping and equipment damage.

Drain lines, vents and other small diameter fixtures that are unlikely to produce any measureable heat transfer loss from the system often remain uninsulated, ignoring the threat of constant sweating and exterior pipe wall loss.

11. Wet Pipe Insulation

Enough water can be hidden inside pipe insulation to suggest an actual piping failure when opened. This is due to the fact that fiberglass insulation offers very little true moisture barrier and allows humidity to condense at the cold pipe surface.

Wet insulation is therefore a sure sign of some form of a problem with fiberglass insulation; water will eventually penetrate to the outside to produce wetness, discoloration, and crystallization, thereby providing telltale evidence of a problem. If acted upon, corrosion under insulation (CUI) problems can be avoided and the often mild deterioration present at early stages of such a problem can be corrected. If allowed to continue, substantial piping damage is likely.

An aluminum or vinyl jacket covering over otherwise improperly or insufficient insulation can actually hide the build-up of water at the pipe and allow years of additional damage to take place. In multiple cases where grooved or clamped pipe was in use, the accumulation of water inside its vinyl elbows, tees or other fittings severely deteriorated the absolute weakest link in the entire piping system—its connection bolts—to cause catastrophic failure.

12. Mold Contamination

Cold water pipe, insulation failure and area humidity produce condensation and wet pipe conditions, which are a prerequisite to mold growth. Mold typically develops at HVAC system piping after an extended period where wet pipe conditions have existed, and where years of opportunity likely existed to correct the problem long before it began.

While not related to its corrosion condition or contributing to a failure of the pipe itself, the presence of mold typically raises all forms of health issues, which are in many cases followed by very aggressive and costly legal action. Water leaks due to pipe failure behind walls, overflowing condensate drains, and other sources of water will produce the same result.

The replacement of all pipe insulation and sheetrock walls is often the only solution for a mold condition. Although not technically a piping corrosion problem unless the water-saturated insulation has destroyed the piping as well, widespread mold contamination can result in losses well exceeding the cost of pipe replacement alone.

13. Microbiologically Influenced Corrosion

Microbiologically influenced corrosion (MIC) is, by far, the most severe and threatening form of corrosion to HVAC piping and fire protection systems. It is caused by the presence of various microbiological agents under specific environmental conditions and can, in some cases, result in an advanced and widespread failure of entire piping systems within only a few years.

A MIC presence usually signals a very severe threat to the entire system, requiring extensive cleanings and repeated sterilization at great expense. (To learn how to detect MIC, see the article Testing For Microbiologically Influenced Corrosion in Pipelines.) For many affected systems, MIC cannot be eliminated, and an elevated corrosion and pitting condition will exist for the remainder of the life of the system.

Microbiologically influenced corrosion produces large and deep pits due to its utilization of the steel pipe itself as an energy source (often as an alternative to oxygen), as well as through the production of strongly corrosive metabolic by-products, such as sulfuric acid, which further assist the microorganism in dissolving pipe metal.

MIC exists to varying degrees of severity, and is not exclusive to carbon steel piping systems or open condenser water systems. MIC is commonly found in closed chill water piping, especially those winterizing with glycol, and has been documented to destroy copper, brass and stainless steel pipe.

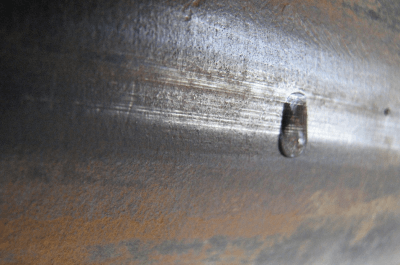

14. Seamed Pipe

35 years ago, the standard piping specification for all HVAC and fire protection systems called for ASTM A53 grade B seamless stock. This is due to the well-recognized higher failure rate and vulnerability of seamed or welded pipe. Today, it is difficult to find seamless pipe installed unless it was specified in its design.

Seamed pipe has not become better manufactured; it’s just cheaper. Seamed pipe has a greater vulnerability to corrosion at the seam due to many causes. In many examples, poor manufacturing practices produce an internal or external seam that is incomplete.

On the inside, this incomplete weld seam then becomes a focal point for rust and microorganisms to establish and promote higher corrosion activity, often leading to pinhole failure. A common dissimilarity in electrical potential between the pipe itself and weld filler presents another threat. The zinc protective coating at the weld is sometimes lacking for seamed pipe, initiating a very premature yet defined line of galvanic attack.

Defective seamed pipe is widespread throughout the foreign market. It is less common in better U.S. piping manufacturers but still present. Under low-corrosion conditions, defective seamed pipe can still produce system-wide failure problems, but under the higher corrosion conditions often encountered today, it can amplify the threat and consequences of a severe corrosion problem.

15. Grooved Pipe Failure

Grooved piping is a well-respected and proven pipe assembly process and method with decades of success. Most failures occur due to either incorrect installation or a severe corrosion condition. Where the outer groove is swaged or rolled into place, the pipe wall is displaced internally and no actual wall loss occurs.

Where the groove is cut into the outer surface, substantial pipe wall is removed—similar to the wall loss of a threaded pipe.

As a result, any high-corrosion condition will reach the base of that outer cut groove first to produce a failure ranging from a pinhole leak to a total pipe separation. And because of the depth of the cut groove, no prior indication of a corrosion loss may have occurred to other areas of pipe.

In addition, the end gap between piping sections often allows another corrosion front to act against the pipe from its end dimension.

Due to the potential for far greater than just a pinhole failure and the possibility of total pipe separation, any leaks at a grooved clamped fitting should be investigated thoroughly.

16. External Corrosion

We have documented more pipe damage due to external (outer surface) corrosion than internal causes. Most is due to insulation failure and the fact that it is hidden from view until a leak, maintenance or some other event prompts a visual investigation.

For uninsulated pipe, such as roof level condenser water lines, a surprisingly high volume of pipe is left to deteriorate and could have been avoided through simple maintenance.

The severity of an outer surface corrosion problem can be misleading, but with approximately 18 times as much less dense rust produced from its original volume of pipe steel. In most examples, surface rust is minor and can be easily addressed by the maintenance staff by mechanical wire wheel and the application of an effective rust reverser and outer protective coating.

Left to continue, surface rust develops into stratified layers under which deep pitting accelerates, and against which only sand blasting will prove effective at its removal.

17. Cooling Tower and Exchanger Corrosion

The first sign of a corrosion problem is usually revealed at the cooling tower. Rust deposits at the pans represent the pipe wall that was once part of the circulating system. White deposits at the tower fill represent a potential scaling condition.

Discolored and turbid water are yet another indication that corrosion activity is high and that chemical water treatment is lacking. Algae and other organic growths not only interfere with operations, but also accelerate many other corrosion processes and promote microbiologically influenced corrosion.

In many cases, cooling tower maintenance and the removal of rust deposits is performed without ever investigating the underlying cause of the problem—and without considering that the volume of rust deposits exposed at the tower is nothing compared to the volume of rust deposits still inside and firmly attached to its walls.

Most heavy rust deposits are produced after decades of high corrosion activity, only falling loose to be carried to the cooling tower after some form of shock to the system, such as a spring start-up or temperature change. They are rarely captured by most filtration systems or removed or dissolved by most chemical adjuncts.

18. Corrosion due to Soft Foam Pipe Insulation

Soft foam insulation allows moisture to infiltrate to cold pipe surfaces and produce destruction of the steel pipe common to fiberglass insulated systems. Over a relatively short time, soft form insulation deteriorates—hardening, cracking and shrinking to produce large gaps for moisture to enter.

In addition, the foam actually degrades chemically to become slightly acidic, bonding itself to the pipe or rust layers so securely that removing old soft foam insulation becomes extremely difficult.

Where high humidity is present and condensation to a cold pipe surface is a serious concern, hard cell "foam glass" insulation is overwhelmingly recommended. As a second choice, a heavier thickness of fiberglass, painted with a high solids coating to act as a moisture barrier, is an option. Soft foam insulation should only be used for temporary or short-term applications.

19. Copper Pipe Corrosion

High corrosion losses at copper pipe resulting in failure are rare. Contrary to common belief, however, copper is not immune to the effects of corrosion. Corrosion conditions resulting in high corrosion losses against steel pipe, and possibly producing a corrosion rate 10 times above normal, will also produce an equally elevated corrosion rate against copper components.

Although a 0.3 MPY corrosion rate against copper is normal for an HVAC piping system, high corrosion rates of 3–4 MPY have been measured.

Failures at copper piping systems are mostly related to specific conditions or events, such as acidic and low pH water, galvanic activity and improper grounding or stray voltage, or high steel corrosion activity resulting in the migration of iron oxide into the copper lines.

20. Brass Dezincification

Brass is found less and less at most commercial properties, having been replaced by easier to install and far cheaper Type L copper pipe. Corrosion activity at brass pipe is typically very low, allowing it to easily provide nearly 100 years of reliable service life.

Under certain water quality conditions, however, and where the water supply is more aggressive, the zinc chemical component is leached out of the brass to produce small pinhole failures or fractures and splits. Greenish-white deposits are a common signature of dezincification, which can be confirmed by metallurgical lab analysis.

Most dezincification occurs where water quality is aggressive yet still requires 75 or more years to occur, a length of time generally exceeding the expected service life of most building structures.

Brass is commonly found at older domestic hot water piping systems instead of galvanized pipe due to the effect that the heat has against the zinc protective coating. With the galvanized steel pipe always failing first, and given access difficulties in any domestic pipe replacement projects, the brass hot water component is also replaced, making brass pipe an increasingly less common concern.

21. Steel-to-Steel Electrolysis

Microvolt differences in ground potential between building piping and the building's structural steel has been cited in some examples of very localized pipe failures. This normally occurs at steel piping supports and hangers, and with direct metal-to-metal contact.

Requiring highly sensitive electrical instruments to make a positive diagnosis, ultrasonic testing performed further removed from the area of failure will often show far less and even normal corrosion activity.

Although this form of electrolysis rarely occurs, we consider it prudent to insulate metal to metal contact, and especially where steel pipe is exposed to water, cooling tower overspray, and other weathering conditions.

Chemical treatment is a potential solution for many internal pipeline corrosion problems. Washing the pipe with a chemical solution removes any corrosion products. Coating and protection of the lining of the pipe by pumping chemicals is next in the process. Re-coating is common for external treatment treatment of the pipe. The same treatment can be applied to any corroded metal. The rust and corrosion is first cleaned from the metal, then the pipe is coated with a specially-designed coating to protect it.

***This content was reprinted with permission from Corrview.com. All images sourced from: Corrview.com