What Does

Stress Concentration Factor (Kt) Mean?

A stress concentration factor (Kt) is a dimensionless factor that is used to quantify how concentrated the stress is in a mechanical part. It is defined as the ratio of the highest stress in the part compared to a reference stress.

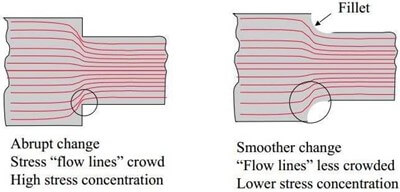

A stress concentration, also known as a stress riser/raiser, is a point in a part where the stress is significantly greater than its surrounding area. Stress concentrations occur as a result of irregularities in the geometry or within the material of a component structure that cause an interruption of the stress flow. These interruptions typically arise from discontinuities such as holes, grooves, notches and fillets. Stress concentrations may also be caused by accidental damage such as nicks and scratches.

A discontinuity’s degree of concentration under typical tensile loads is usually expressed by the non-dimensional stress concentration factor (Kt), which is the ratio of the highest stress to the reference (far field) stress:

Note that the reference stress is the total stress within an element under the same loading conditions, but without any stress concentrators (i.e., the total stress on the part when it is free from discontinuities).

An understanding of the stress concentration factor is important during the material selection process as well as for anticipating stress corrosion cracking, fretting corrosion and material failures.

Corrosionpedia Explains Stress Concentration Factor (Kt)

Basic stress analysis calculations assume that parts are smooth, have a uniform cross-section, and have no irregularities. In practice, virtually all engineering components have at least minimal changes in section and/or shape.

Shoulders on shafts, oil holes, key ways and screw threads all can change the stress distribution such that the basic stress analysis equations no longer apply. Such discontinuities cause a local increase in stress, referred to as a stress concentration factor.

If the material is flawless with no discontinuities, then the stress concentration factor is 1. If there is a discontinuity, then the stress concentration factor is greater than 1.

How Stress Concentration Factor (Kt) Values are Determined

The stress concentration factor associated with a part’s specific geometry and loading condition can be derived through experimentation, analysis or computational methods.

- Experimental methods: Optical methods such as photoelasticity are very dependable and widely used for experimentally determining the stress concentration at a point on a part. However, several alternative methods that have been historically used include the grid method, brittle coating, brittle model and strain gauge.

- Analytical methods: The theory of elasticity can be used to analyze certain geometrical shapes to calculate stress concentration factors.

- Computational methods: Finite element techniques provide a powerful and inexpensive computational method to assess stress concentration factors.

Characteristics of a Stress Concentration Factor

- Function of the geometry or shape of the part, but not its size or material composition

- Function of the type of loading (axial, bending or torsional) applied to the part

- Function of the specific geometric stress raiser (e.g., fillet radius, notch or hole) in the part

- Always defined with respect to a particular nominal stress

- Typically assumes a linear elastic, homogeneous, isotropic material

Methods to Reduce a Part’s Stress Concentration Factor

A number of stress-relieving methods are available to reduce the stress concentration factor of a given part, including:

- Providing a fillet radius so that the cross-section may change gradually

- Using an elliptical fillet

- Using several small notches rather than a long one, if a notch is unavoidable

- Using narrow notches rather than wide notches, if a projection is unavoidable

- Using stress-relieving grooves