Of the types of environmentally assisted cracking of austenitic stainless steel, chloride stress corrosion cracking (Cl-SCC) is the most common. (For an introduction to this topic, be sure to read Chloride, Caustic and Polythionic Acid Stress Corrosion Cracking.)

Cl-SCC has been the observed cause of failure in numerous scenarios, from medical devices to condenser tubes in heat exchangers to swimming pool components to parts used in marine applications to under insulation of external piping in a refinery. Even when a process stream does not contain any chlorides, a hydrotest with chloride-contaminated water and left to dry can result in Cl-SCC because the concentration of chlorides collects into small pools on the metal's surface. Thus, although Cl-SCC is a well-known failure mechanism, its occurrence is often unexpected.

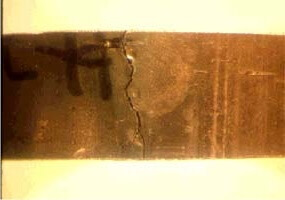

Figure 1. Stress corrosion cracking caused by chlorides leaching from insulation onto stainless steel's hot metal surface. (Source: NASA Corrosion Engineering Laboratory.)

Environmental Factors that Impact Chloride Stress Corrosion Cracking (Cl-SCC)

Cl-SCC often initiates from sites of localized pitting attack or crevice corrosion and occurs when the crack grows more rapidly from the pit or crevice than the rate of uniform corrosion. (Related reading: Understanding Pitting Corrosion to Prevent Catastrophic Failures.) For Cl-SCC to initiate requires the presence of both chloride ions (Cl–) and a tensile stress. However, other environmental factors can impact the crack initiation process, and these include temperature, pH, oxygen level and humidity.

Many suggest that a temperature above 60°C (140°F) is required for Cl-SCC, but there have been many reports of Cl-SCC occurring at 50°C (122°F) or lower. Above 80°C (176°F) initiation of Cl-SCC can be very rapid; thus, excursion temperatures and length of time at temperature can be critical factors as to the initiation and propagation of Cl-SCC.

The level of chloride to produce Cl-SCC is a function of the tensile stress with higher tensile stresses requiring lower Cl– concentration. Failures have been reported in environments as low as 10 ppm Cl– because a few ppm Cl– in the process stream can concentrate to hundreds of ppm in the area of evaporation. Once pitting corrosion initiates, Cl– can further concentrate at the base of the pit. Although higher molybdenum (Mo) content in the austenitic stainless steel can improve the pitting resistance, the susceptibility of these alloys to Cl-SCC still remains.

The tensile stress below the macroscopic yield stress is sufficient to initiate Cl-SCC. Higher stresses impact the propagation of the crack although it is the strain at the crack tip that is the critical factor. The tensile stress can either be applied or residual, as for example from welding. Crack propagation rate is more of a function of temperature than stress level.

Oxygen level is another an important factor for Cl-SCC. If the oxygen level is in the 0.01 to 0.1 ppm range, aqueous solutions containing low to moderate levels of Cl– are less likely to crack an austenitic stainless steel. Note that the O2 solubility in water at around 60°C is about 8 ppm and thus is often considered to be a contributing factor. At higher temperatures of 250 to 300°C (480°F to 570°F), the presence of oxygen is a major factor in Cl-SCC.

Lower pH can initiate Cl-SCC at a low Cl– concentration. To some extent a higher pH has been shown to provide some immunity. However, it is the pH or H+ concentration at the crack tip, and not the pH of the process stream, that is the critical factor for crack initiation/propagation. As noted in Chloride, Caustic and Polythionic Acid Stress Corrosion Cracking, caustic cracking can occur in strong caustic solutions.

Hydrogen sulfide (H2S) seems to have a synergistic effect on Cl-SCC with Cl-SCC being observed at ambient temperatures with relatively low Cl– concentrations.

Organic chlorides can be hydrolyzed by water to produce hydrochloric acid (HCl). Thus, the presence of an organic chloride combined with water in a process stream has the propensity to cause Cl-SCC.

Counteracting Cl-SCC

When a metallurgist or corrosion engineer is asked to specify an austenitic stainless steel for an application, the first question that is asked is whether there are any chlorides in the process stream or environment and if present can they be reduced or the temperature changed. For example, the temperature may be elevated by adding insulation to prevent condensation on the metal surface or a temperature quench of the process stream where a nickel-based alloy is being used.

Changing process conditions is the best approach for minimizing Cl-SCC. When not feasible, applying compressive stress by shot peening is a possibility but such compressive stresses cannot always be maintained because of post-fabrication welding and assembly of components that do not perfectly align producing residual tensile stresses. The same comment can be made for utilizing a stress relief anneal of the final assembly to remove residual tensile stresses.

Chemical inhibitors can minimize the potential of Cl-SCC by preventing acidification at sites of local corrosion or by modifying the electrochemical potential outside the range for Cl-SCC. However, the specific chemical inhibitor and its concentration with the process stream must be first evaluated and continuously monitored to establish its effectiveness.

Upgrading the metallurgy to another alloy is another viable approach. For example, a duplex stainless steel might be considered. A duplex stainless steel has a two-phase microstructure consisting of an approximately 50/50 mix of austenitic and ferritic grains but has temperature limitations compared to austenitic stainless steels. Duplex alloys have excellent corrosion resistance with high pitting resistance (PREN); these alloys have higher threshold stresses and temperatures of about 130°C (266°F) for susceptibility to Cl-SCC. Likewise, ferritic stainless steels are considered to possibly resist cracking depending on composition but also have temperature limitations. Alloys with higher Ni content such as the super austenitic stainless steels tend not to crack in Cl– environments. Alloy 825 is another reasonable alternative. (Related reading: Understanding the Relationship Between Stress and Corrosion.)

Crack Morphology

Cracking morphology is initially transgranular or through the metal grains by a cleavage mechanism. Often there might be multiple initiation sites and the crack can be highly branched. It may transition to an intergranular (along the grain boundaries) mechanism prior to ductile final fracture.

Heating an austenitic stainless steel to 400°C to 800°C (750°F to 1470°F) for a specific period of time such as during operation or welding a high carbon stainless steel can cause precipitation of chrome-rich carbides in the grain boundaries. A stabilized grade such as type 321 or 347 will take longer for this to occur than a high carbon type 304H. The result is chromium depletion along the grain boundaries producing a continuous path of lower corrosion resistance along the grain boundaries. (You may be interested in reading: The Role of Chromium in Intergranular Corrosion.) The crack morphology will be branched and intergranular.

Although the initiation of Cl-SCC is by localized corrosion, the mechanism of crack propagation is complicated and not fully understood. The most popular mechanisms are slip dissolution, hydrogen embrittlement and film-induced cleavage or their combination.

CI-SCC due to Welding

Cl-SCC failures are often associated with a weld because the welding operation introduces residual stress in the weld area. In the immediate weld area, peak stresses may exceed the threshold stress for Cl-SCC. With the advent of dual certified traditional austenitic stainless steels, chromium-carbide precipitation in the grain boundaries from welding with increased susceptibility to Cl-SCC is no longer an issue.