Pipeline pigs are an essential tool for maintaining pipelines. This article examines pipeline operational pigging for internal corrosion prevention, including pigging requirements, pig types, pig selection, frequency of operation and evaluating the results from pig runs in order to optimize the pipeline’s total cost of ownership. (For more pipeline corrosion prevention tips read Corrosion Prevention for Buried Pipelines.)

What is a Pipeline Pig?

A pig is a free-traveling device inserted into a pipeline and driven by the product flow. A proper pig selection and pigging program will help to maintain the integrity and efficiency of the pipeline. Pig traps must be located at the beginning (launcher) and end (receiver) of the pipeline, which allows inserting the pig into the pipeline without flow interruption. While in use, the location of the pig can be determined through tracking devices as well as pig detectors.

How Pigs Help Pipelines

Pigs play a major role in ensuring the continuous operation of the pipeline through a combination of the following:

- Maximizing fluid transportation

As pipelines transport fluids between production facilities or to costumers, scale may build up and negatively affect the pressure and flow, making the pipeline less effective. Pigs help by removing scale and ensuring the proper flow and pressure are maintained throughout the pipeline’s service life.

- Internal corrosion control

Internal corrosion is one of the most common threats to a pipeline, and if not tackled properly it can cause severe integrity issues that can lead to loss of containment, environmental impacts and others. Pigs are used to clean the internal surface of the pipeline by removing debris and also displacing liquids. This will prevent deposit corrosion, and improve the distribution of corrosion inhibitors and facilitate chemical batching.

- Pipeline construction and commissioning

During construction, hydrostatic testing is a critical stage of the process. Before and after this stage, pigs are used to clean debris and displace gas or liquids. This step is important to prevent premature internal corrosion in the line. Gauging pigs are also used to prove pipe roundness and ensure that no excessive debris or weld penetration exists prior to commissioning. (To learn more about weld corrosion, see An Overview of Welded Joint Corrosion: Causes and Prevention Practices.)

- Collection of pipeline data

Before an in-line inspection is done, a pig is used to verify the minimum bend radius and that the pipeline is clean. This can ensure a successful run, which is imperative considering the high cost of this type of pig. In-line inspections are done with intelligent smart pigs that can give further information (such as temperature, elevation, wall thickness and anomalies) about the pipeline along its entire length. This provides assurance of the pipeline’s integrity.

Defining Pigging Requirements

Pigging requirements should be defined based upon the pipeline’s material selection (e.g., carbon steel) and the expected threats or corrosion mechanism. The main corrosion mechanisms in the oil and gas industry for carbon steel pipelines are CO2 corrosion, H2S corrosion, microbiologically influence corrosion (MIC), oxygen corrosion or a mixture of these. Pigging helps to mitigate these threats.

How Pigging Mitigates Each Corrosion Mechanism

There are several mechanisms that can induce pipeline corrosion, each of which can be mitigated by pigging.

When it comes to CO2 corrosion in carbon steel pipelines, pigging supports the effectiveness of an injected corrosion inhibitor by ensuring proper distribution (including top of the line) and allowing the chemical to reach the pipe wall. Pigging also helps preventing debris buildup, consequently minimizing the possibility of chemical adsorption (to prevent localized shielding) and under deposit corrosion. It also reduces stagnant water pools from forming at low points in the pipeline.

As is the case with CO2 corrosion, H2S corrosion mitigation is improved by pigging. An additional factor that contributes to a higher corrosion rate in this mechanism is sulfur deposits. If sulfur deposits are present then a good industry practice is to batch between two pigs.

Oxygen can significantly increase the internal corrosion rate in a pipeline. De-aeration cells can occur in the presence of scale or debris. In sour environments, oxygen can react with H2S to produce elemental sulfur. Pigging can mitigate both threats by removing the solids.

- Microbiologically influenced corrosion (MIC)

Mitigating the threat of bacteria in a pipeline is done by biocide injection, which should be accompanied with pigging to ensure the batch effectiveness. Pigging is essential to remove any debris, solids, sand, bacterial slimes, biofilm and tubercules that are on the surface of the pipeline. If they are not removed, the biocide may not be able to permeate and kill the bacteria.

Types of Pipeline Pigs

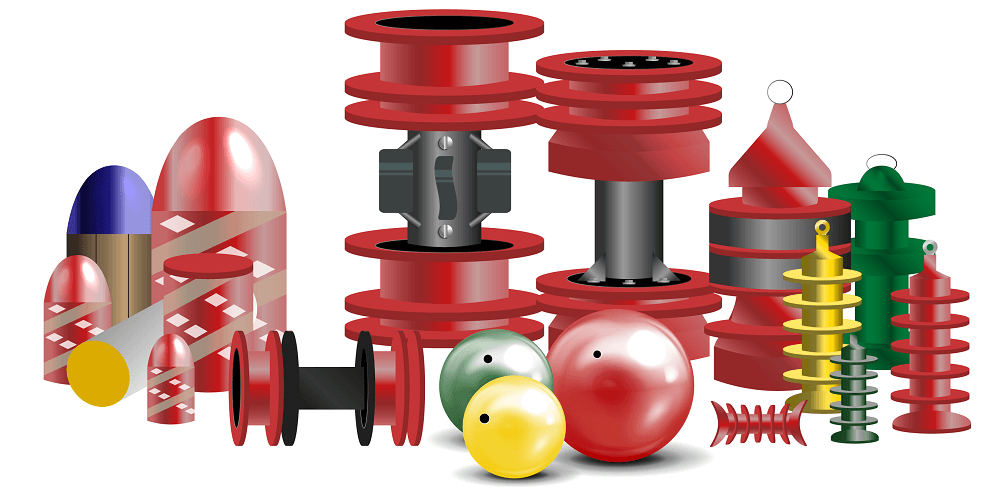

As mentioned previously, when it comes to corrosion prevention, pigging may be required for cleaning, displacement or for bathing purposes. In all cases utility pigs are used (Figure 1).

Figure 1. Utility pigs

Based upon their purpose, utility pigs are divided into two main groups:

- Cleaning pigs are used to remove solid deposits or debris

- Sealing pigs are used to provide a good seal in order to sweep liquids or create an interface between two products (e.g. a chemical batch)

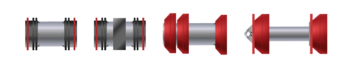

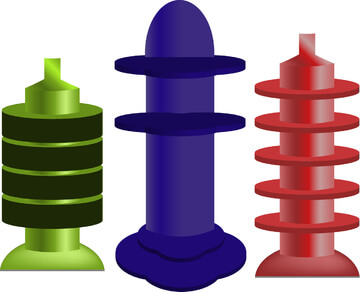

These groups can be further subdivided into mandrel pigs (e.g. steel mandrel pig, Figure 2), solid cast pigs (Figure 3), spherical pigs (Figure 4) and foam pigs.

Figure 2. Steel mandrel pigs

Figure 3. Solid cast pigs

Figure 4. Spherical pigs

Pigs are constructed from different materials depending upon the pig type and its intended purpose. Table 1 describes common materials used to construct utility pigs and their typical applications.

|

Pig Type

|

Material

|

Applications

|

Additional Remarks

|

|

Mandrel pig

|

Carbon steel or stainless steel body with polyurethane, neoprene, or rubber cup/discs

|

Cleaning

Swabbing

Batching

Separation

Displacement

|

Cup (uni-directional) or Bi-Di (bi-directional, can travel on both directions).

Can add gauging plates, brushes, magnets, trackers and transmitters.

Bi-Di pigs require the highest differential pressure to drive the pig through the pipeline in comparison to cup pigs and the other utility pigs.

Pigs tend to vibrate, which can loosen parts (bolts and nuts) and cause pig failure.

|

|

Solid cast pig

|

Polyurethane

|

Swabbing

Batch chemical

|

Available with brushes and bypass nozzles.

|

|

Spherical pig (spheres)

|

Rubber or thermoplastic, solid (polyurethane/neoprene) or inflated with water/glycol

|

Separate batches

|

Fewer operational requirements (least driving pressure).

Bi-directional.

May have automated launching. Inefficient for cleaning or swabbing.

|

|

Foam pig

|

Polyurethane foam

|

Batching

Separation

Cleaning

Swabbing

|

Density varies (low, medium, high).

Can negotiate pipe reductions and restrictions.

Good for progressive pigging. Can have brushes to remove hard scale.

Receiving baskets are recommended to avoid parts entering into the process facilities.

Inefficient for cleaning or swabbing.

|

Table 1. Utility pig construction materials and applications.

How to Select the Appropriate Pig

Selecting the most suitable pig should be based on the reason for performing the pigging procedure and the pig manufacturer’s recommendations, which are determined by the pipeline’s specifications (diameter, length, fluid, purpose, expected solids, bend dimensions, tie-ins, etc.).

Establishing a pigging schedule and frequency will depend upon several factors, including:

- Breakdown of the protective corrosion inhibitor film that was previously injected during the pipeline’s installation

- Fluid type (e.g., wet gas, oil)

- Water cut (the ratio of water versus hydrocarbons produced from the well)

- Flow regime (possibility of water drop out, water wetting, stratified flow, fluid velocities, etc.)

- Debris deposition

- Amount of debris that accumulates at the pig receiver (for low flow conditions)

- Additional treatment (such as batch inhibition)

- Operational restrictions

Optimizing Pigging Frequency and Pipeline Operation

Pipelines operated with a film velocity (normally the water and condensate) higher than 1 m/s are considered to have a lower risk of debris accumulation (including sand) and therefore doesn’t require as high of a pigging frequency as a pipeline with a lower velocity.

Optimizing the pigging frequency (i.e., more or less often) is accomplished by analyzing the results from a number of pig runs (solid characterization, water amount), data from monitoring (such as corrosion coupons, probes, automated ultrasonic testing (AUT), liquid sampling, process conditions, etc.) and inspection (smart pig). (Have a non-piggable pipeline? Be sure to read Guided Wave Ultrasonic Testing for Non-piggable Pipelines as an alternative method.) A conservative approach should be to progressively reduce the pigging frequency as the supporting data is obtained and assessed; this will ensure optimal corrosion management without affecting the pipeline integrity.