Wear and tear on oil sands equipment represents a serious concern for the oil and gas industry. The cost of lost production output is extremely high. Whenever a part is worn down or breaks, production involving the affected equipment must stop until a fix has been made. The cost of a leak in the processing plant or into the natural environment is expensive. Leaks present hazards to workers, residents and plants and animals beyond the facility. In addition, the cost of equipment, materials and labor to repair or replace a part is costly. The fact that the oil sands industry deals with immense costs is not surprising.

“You’re pumping and moving oil-laden sand at high temperatures through metal machinery. The sand is extremely abrasive. It releases chemicals that make it more corrosive as it heats up,” said Wynn Hollingshead, CEO of Pacific Particulate Materials (PPM), a Vancouver-based custom powder manufacturer.

The Hazards Faced by Oil Sands Equipment

The equipment deterioration occurs in two steps. When sand moves across metal, it attacks the surface of the metal. As the surface wears down, corrosive chemicals further strip the exposed metal below the surface. These two processes speed the rate at which a part is degraded. In addition, when metal parts heat up, the hardness of the parts goes down. (Related reading: 5 Ways to Measure the Hardness of Materials.) This means the wear rate on the machinery increases even further. All of the factors add up to premature part failures.

Specialized Coatings for Oil Sands Equipment

A recent innovation to combat wear is a customized chromium-carbide overlay. The coating can be applied to the interior of metal pipes and tubes, with the coating being up to 0.25 inches (6.35 mm) thick. The coating is applied by plasma-transferred arc welding (PTAW). When applied properly, the chromium-carbide coating combats friction, impact, heat, tar sand erosion and the corrosive materials created by and involved in tar sands processing. (For more on the topic of erosion, read Erosion Corrosion: Coatings and Other Preventive Measures.)

Figure 1. Plasma transferred arc (PTA) welding torch used to apply the new coating to oil sands equipment. (Source: InnoTech Alberta)

The coating works because it creates a heat-resistant surface that is harder than the metal in the pipes and tubes. The chromium-carbide coating also has a high melting point, and is resistant to both abrasion and corrosion.

Each chromium-carbide coating starts out as a customized powder blend. The tricky part of customization is that each oil sands producer has its own PTAW equipment. Each producer also has a unique setup and sometimes unique hardware for tubes and pipes.

Use of the chromium-carbide coating is expected to have a significant positive impact in plants that engage in a process known as upgrading, in which asphalt (bitumen) is transformed into light sweet synthetic crude oil (SCO).

Providing the Chromium-Carbide Powder to Oil Producers

Hollingshead said PPM is capable of creating a range of chromium-carbide powders.

“We work one-on-one with each company’s qualification system to create a powder that fits its PTAW equipment and its equipment needs. We sell the powders to parts manufacturers and hardfacing applicators that coat new parts with it. We also sell it to oil producers that may coat new parts with it or coat parts they already have in their plants,” said Hollingshead.

Hollingshead said differentiating various powder formulations also allows PPM to manufacture compositions specific to customer needs.

“The cost of the materials for this powder is competitive. In addition, there’s the potential work of making tweaks to customize a blend,” Hollingshead said.

Hollingshead said details about cost, composition, effectiveness and longevity of custom powders are kept private through non-disclosure agreements (NDAs) with individual customers.

“How the powders work over time is really only available to those companies that use the parts. They are the ones who observe how well the parts coated with the powder perform and how long these parts last,” said Hollingshead.

PPM is always learning more about how to optimize the powder for purposes like coating metal tubes to transport fluids. In addition, the company used a slow period induced by the COVID-19 pandemic to do more research and development.

“Right now, demand is down substantially, around 50 percent. Oil producers are making less oil in response to the decrease in world oil demand. We’re using this time to improve what we manufacture. With more knowledge, we can create better products,” said Hollingshead.

The Origin of the Powder Coating for Hard Facing

Oil sands producers in Alberta, Canada began looking for a solution to corrosion and wear in metal tubing in 2016. They reached out to Gary Fisher, the principal engineer of materials at InnoTech Alberta, which is a subsidiary of Alberta Innovates, the province’s largest research and innovation agency. The organization is tasked with assisting businesses in the province.

Fisher said his team knew from experience which corrosion-resistant alloys (CRAs) might work best.

“We then set up a project team of around seven people. We worked on increasing resistance to wear for about two years,” said Fisher. When the team came up with a viable powder at the end of 2018, they shared it with Pacific Particulate Materials.

“We contacted PPM so they could take what we developed and refine it further. Now PPM has the opportunity to commercialize the powders,” said Fisher.

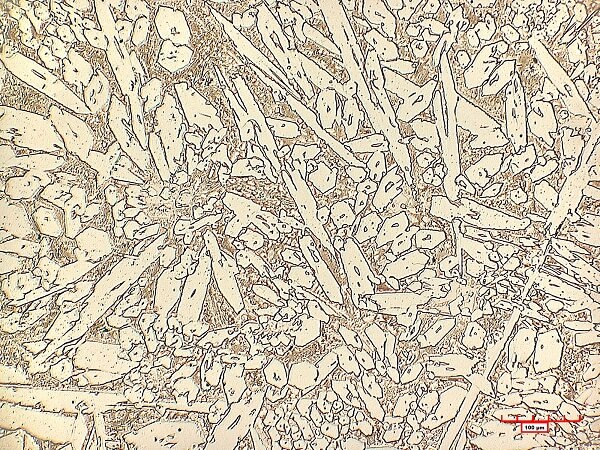

Figure 2. Microstructure of the new coating solution to reduce wear and tear on oil sands equipment. (Source: InnoTech Alberta)

PPM develops powder blends for parts manufacturers and oil producers in over 60 countries around the world. The company makes a variety of ceramic, cermet, and metal powder blends and components.

Hollingshead said his team and Fisher’s team at InnoTech Alberta were in communication between 2018 and 2020.

“During this period, we looked at ways to optimize the powder and account for technical issues like differences in application methods. In August 2020, we were cleared to start producing the powder,” said Hollingshead.

Hollingshead said PPM also used the time to develop potential customer lists and prioritize potential customers.

Still Learning What Works for Corrosion and Abrasion Protection

Fisher said the level of protection afforded by the overlay is dependent on the service environment, which is the physical environment in which the overlay is used.

“We do know that the life of the overlay somewhat depends on the thickness of the coating. Having improved wear resistance should provide cost savings when compared with standard CRAs,” said Fisher.

Dr. Frank Cheng, Canada Research Chair in pipeline engineering at the Department of Mechanical and Manufacturing Engineering at the University of Calgary, is interested in learning more about the powders PPM is developing.

Cheng is the editor-in-chief of the Journal of Pipeline Science and Engineering. He is also the author of two books related to solutions for oil producers, “Stress Corrosion Cracking of Pipelines” (Wiley, 2013) and “Pipeline Coatings” (NACE International, 2017).

Cheng said the chromium carbide overlay technology provides a good solution to resist wear and erosion in the oil sands industry. He is primarily concerned about the coating's toughness.

“Ceramic coatings are usually brittle. When a microcrack initiates for any reason, it can propagate rapidly to fail the material,” said Cheng.

Cheng would like to examine data on the fracture toughness testing under relevant operating conditions. He would also like to know how companies that buy the powder apply it to certain types of pipes, such as welded oil sands slurry hydrotransport pipes.

Cheng said it is difficult to comment on whether the coating will affect industry practices without knowing where the coating will be used and what facilities will be protected.

“I would like to see comprehensive testing results about the properties and performance of the coating. These include microstructure, compositional distribution, mechanical properties like strength, hardness and toughness, and erosive/wear resistance. Tests would be conducted under conditions that are representative of the reality. For example, tests conducted in a multi-phased flow loop, a three-phased flow loop that circulates oil, water and sand, and with an impingement jet are preferred,” said Cheng.

Ensuring a Positive Return on Investment

Hollingshead said data on these results are important. It is also essential to keep a customer’s return on investment in mind.

“An oil producer will likely not spend the money to apply a coating if the cost is so high that they just break even on it,” said Hollingshead.

Hollingshead said the improvement of the powder is primarily driven by the customers’ need to reduce processing and production costs. Improvement is also driven by competition between parts suppliers and between oil producers.

“Understanding what motivates producers and suppliers is what allows us to do a better job. We’ve learned over the course of 25 years of doing business that no two customers have the exact same issues and questions. With time, we hope listening to their needs and working with them to optimize the coating will result in reduced operational cost, more efficient plant operation and a reduction in part waste,” said Hollingshead.

Future Innovations in the Oil & Gas Industry

Bryan Remillard is the oil sands policy manager at the Canadian Association of Petroleum Producers (CAPP), a trade association that represents the upstream Canadian oil and natural gas industry. Remillard said Canada’s energy sector has a long-standing history of technological advances and innovation.

Remillard said oil and natural gas companies have invested billions in research and development over the years.

“(They) are sharing technologies as well as collaborating with innovators, universities and governments to leverage their innovations further, even across industries. Engineers, operators and researchers continue to identify progress opportunities and gaps such as coating solutions to improve efficiencies and reduce costs in the manufacturing of our natural resources. As a leader of clean-tech innovations, the energy sector will continue to work on improving environmental and operational outcomes in the future, while ensuring our country’s investment attractiveness and competitiveness.”