What Does

Hardness Of Materials Mean?

The hardness of a material is defined as its ability to withstand localized permanent deformation, typically by indentation. Hardness may also be used to describe a material’s resistance to deformation due to other actions, such as:

- Cutting

- Abrasion

- Penetration

- Scratching

The type of deformation under consideration when measuring hardness is plastic deformation. In other words, the object or material will not return to its original shape after being deformed, unlike elastic deformation.

Hardness is used in numerous engineering design applications. This property is essential as it directly correlates to the material’s performance and suitability. For example, a component’s resistance to wear generally increases with increasing hardness. This is especially important for mechanical equipment with moving parts, like elevator shafts.

Hardness is not a fundamental material property, so it should be viewed in context with other properties such as strength, elasticity and ductility to understand how these properties relate to each other. For example, while a material may be hard, it can also be brittle. This attribute can limit the material’s usage in specific applications.

Material hardness is measured using a hardness test. The value of hardness is dependent on several factors, such as:

- The load on the indenter

- The nature of the load (impact, continuous loading)

- Load duration

- Indenter geometry

Corrosionpedia Explains Hardness Of Materials

Materials will exhibit different hardness measurements under different types of loading. For instance, a material that performs well under a short-duration, high-impact load may not perform as well when subjected to a continuous long-duration load.

Therefore, hardness tests should be carried out under various load conditions to ensure that well-informed engineering and design decisions can be made.

Types of Hardness

The three main types of hardness are scratch, rebound and indentation hardness. Each of these parameters is measured using different tests that use different sets of tools. Below, we will discuss these hardness types in detail.

Indentation Hardness

Indentation hardness is a material’s resistance to permanent deformation due to a localized continuous load. During indentation hardness tests, the test subject is subjected to a continuous point load until an impression is formed.

Indentation hardness tests are one of the most common hardness tests performed across several industries as materials are often subjected to continuous loading in real-world applications. This type of hardness is typically measured on a scale known as the Rockwell Scale.

Figure 1. Rockwell hardness testing equipment. (Source: Sorapol Ujjin / Dreamstime.com)

Scratch Hardness

Scratch hardness, as its name implies, is a material’s ability to resist scratches and abrasion on its surface. These scratches are typically narrow deformations caused by the removal of material due to contact with a sharp, harder material.

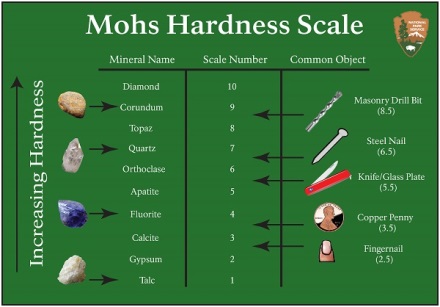

Scratch hardness tests are usually performed on brittle materials, such as ceramics and minerals because they do not undergo plastic deformation. This type of hardness is quantified on a scale known as the Mohs Scale, which is based on the relative scratch hardness of various materials. On this scale, talc is assigned a value of 1, while diamond is assigned a value of 10.

Figure 2. Mohs hardness scale. (Source: https://www.nps.gov/articles/mohs-hardness-scale.htm)

Rebound or Dynamic Hardness

Rebound hardness is concerned with a material’s elastic hardness, as opposed to its plastic (indentation) hardness. During rebound hardness tests, the material absorbs the impact energy from a diamond-tipped hammer and returns it, causing the hammer to bounce after it strikes the surface.

The Leeb rebound hardness test (LRHT) is one of the most popular methods used for measuring the rebound hardness of metals.