Wet abrasive blasting (also known as Vapor Abrasive™ blasting or slurry blasting) is commonly performed to clean a surface (e.g., to remove corrosion, scale, mold or old, worn coatings) or to prepare the surface by creating an anchor pattern for the future application of a coating. (Get a primer on surface preparation in the article Substrate Surface Preparation for Corrosion Prevention.)

Achieving optimum quality and performance requires an understanding of the blasting equipment’s components and how they interact to produce the most appropriate blast pressure for the job at hand.

What is Blast Pressure?

Blast pressure is the pressure of the air, or air and water in the case of wet abrasive blasting, used to propel the blasting media through the blasting nozzle and onto a work surface. Blast pressure is typically measured in pounds per square inch (psi), although it may also be measured in pascals (Pa), kilopascals (kPa) or bars (1 bar equals 100,000 Pa).

A higher blast pressure can clean or prepare a surface quicker because it imparts more energy onto the surface by increasing the velocity of the abrasive media and delivering more kinetic energy.

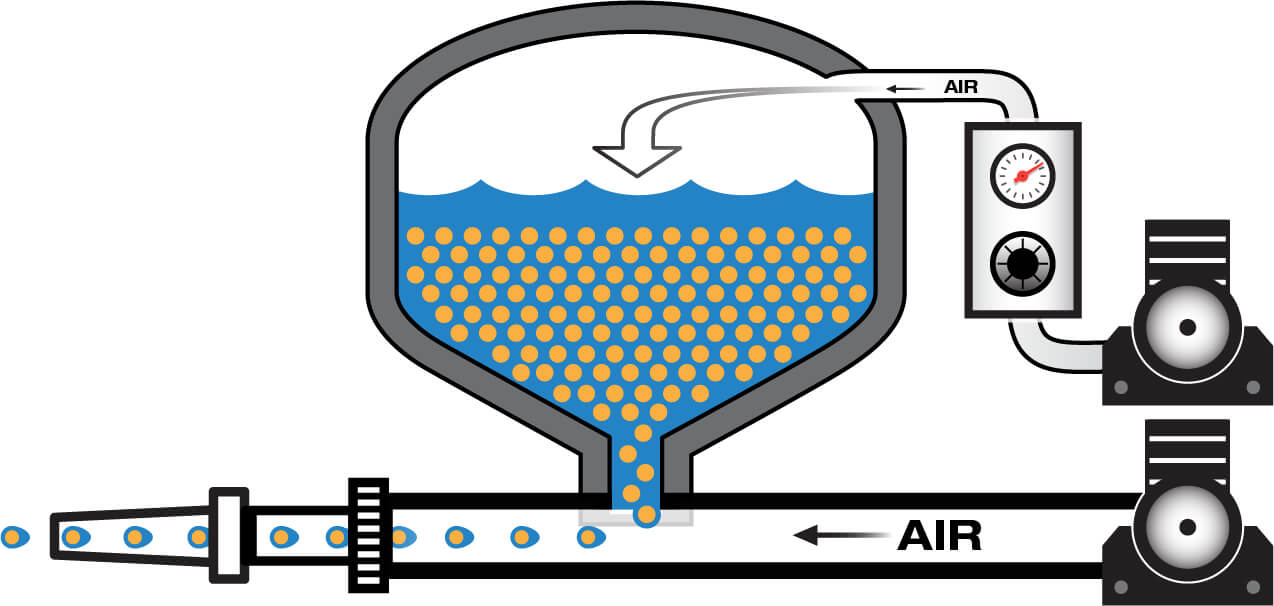

A typical wet abrasive blast pot.

A typical wet abrasive blast pot.

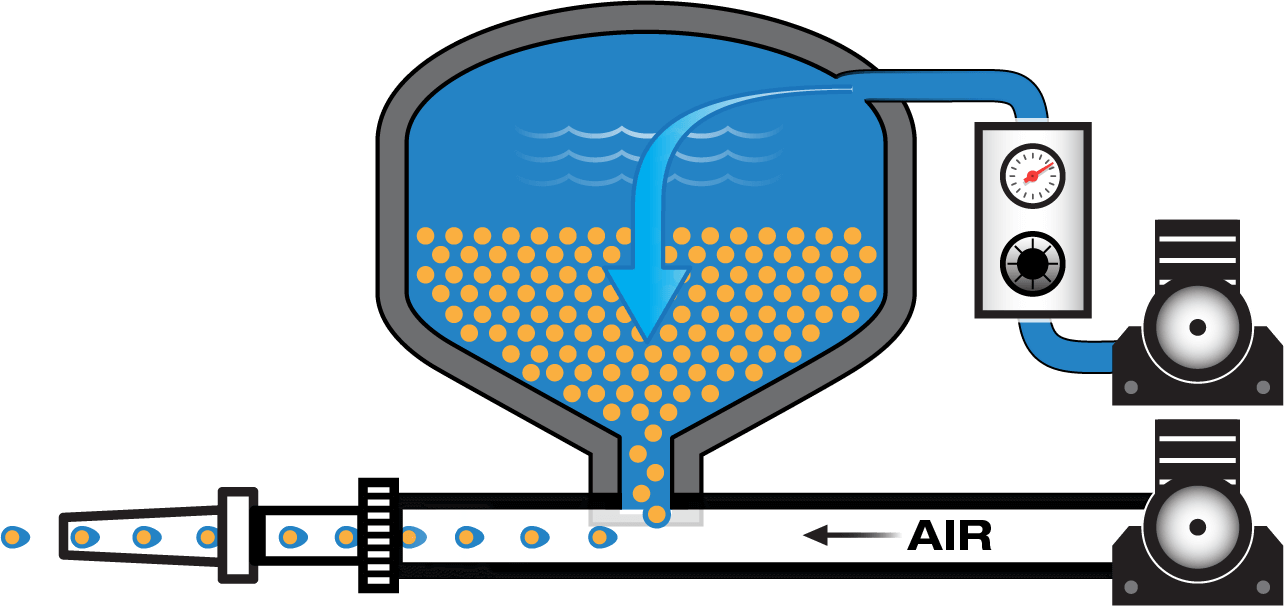

A GRACO Vapor Abrasive blast pot.

A GRACO Vapor Abrasive blast pot.

Read: What is Wet/Vapor Abrasive Blasting

Why Blast Pressure Matters

Each job is unique and requires forethought to achieve the best results. Tough, thick coatings, corrosion, or strongly adhered surface contaminants require a higher blast pressure. Conversely, a lower pressure is sufficient for easy-to-remove coatings or loose dirt.

The material makeup of the substrate and the substrate’s condition should also be considered. Wooden materials (e.g., decks) can be cleaned by vapor abrasive blast cleaning if the blast pressure is low enough to prevent damaging the wood fibers. Being able to fine tune the blast pressure is of immense benefit when removing strongly adhered coatings from delicate substrates because the substrate can be damaged when the coating is removed.

Image: GRACO

Image: GRACO

How to Determine the Correct Blast Pressure for Your Application

The first question to answer is what blast pressure is required to prepare the surface effectively. Some general guidance in the form of Table 1 is helpful to gain a starting point.

|

Blast Pressure (psi)

|

Appropriate For

|

|

25 – 55

|

Monument restoration and cleaning

Soft stone, wood and aluminum

Graffiti removal

Cleaning parts

|

|

55 – 90

|

Concrete cleaning

Building restoration

Line stripe removal

Pitted paint removal

Rust removal

Loose mill scale removal

|

|

90 – 120

|

Concrete surface preparation

Exposing aggregate

Steel surface preparation

Mill scale removal

Coating removal

|

|

120 – 175

|

White metal blast to near white metal blast

Tight mill scale removal

Layered coatings removal

Polyurea removal

|

Table 1. Typical blast pressure (in psi) required for various applications.

Another consideration is the stand-off distance, which is the length between a blasting nozzle and the surface being cleaned. A certain stand-off distance might be required for safety reasons to protect personnel, or it might be influenced by the workspace’s physical conditions, such as nearby objects that restrict access to the surface. The closer the blast nozzle is to the surface to be cleaned, the greater the impacting force and the smaller the blast pattern.

How Equipment Factors into the Equation

There are three important components to a wet abrasive blasting system: the air compressor, the blast hose, and the blast nozzle. Each has a role to play, and the requirement or selection of one affects the others.

Air Compressor

The air compressor collects air at atmospheric pressure and compresses it into a smaller volume at a higher pressure. The greater the amount of air volume that is compressed per minute, the greater the pressure in the blasting system. This increases the production rate for two reasons. First, a high pressure increases the velocity of the abrasive media, delivering more kinetic energy and creating a deeper anchor pattern. Second, a higher pressure allows you to use a blasting nozzle with a larger inside diameter, which puts more abrasive on the surface per unit of time.

Air compressors are sized by how many cubic feet per minute (CFM) of air they compress. Small jobs with detailed work or easy to remove coatings require 185 CFM or less. Compressors in the 115 – 185 CFM range are ideal for small to medium-sized applications. Large, high production jobs or coatings that are difficult to remove require 300 CFM or greater.

Blast Hose

The blast hose plays a simple but critical role – to transport air, water and media to the blast nozzle.

A smaller diameter hose results in a higher blast pressure. Table 2 provides general guidelines for selecting a hose based upon the airflow required for the job.

|

Required Air Flow (CFM)

|

Blast Hose Diameter

|

|

1 – 100

|

0.5-inch

|

|

100 – 300

|

1.0-inch

|

|

300+

|

1.25-inch

|

Table 2. General guidelines for sizing the blast hose.

Blast Nozzle

The blast nozzle receives air from the air compressor and compresses the air even more into a small tube with a diameter generally less than an inch.

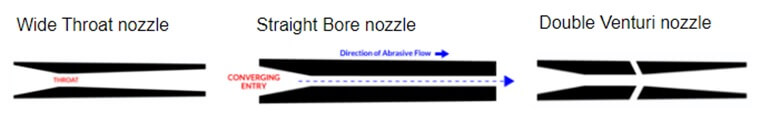

Blast nozzles are available in different form factors or geometries, some of which are depicted in Figure 1. The nozzle’s geometry can affect the velocity of the media exiting the nozzle, the media usage rate and the size of the blast pattern.

Figure 1. Side view of various blast nozzle geometries.

The blast nozzle throat dimension and geometry affects system performance, blast hose selection and system settings, because it controls the maximum airflow at the desired blast pressure. A smaller diameter nozzle results in a higher blast pressure.

Blast nozzles are labeled by the throat diameter in 1/16-inch increments. Thus, a #5 nozzle has a 5/16-inch diameter.

Read: How to Choose the Right Blast Nozzle

Doubling the diameter of the nozzle’s orifice will quadruple the area of the orifice and the volume of air and abrasive media that passes through the nozzle. To maximize productivity, choose the biggest nozzle that the air compressor will support at a pressure that will be productive.

Due to erosion from the constant stream of water and abrasive media, the diameter of the nozzle’s throat gradually increases in size. This is something to keep in mind when sizing a particular nozzle for the job at hand because the nozzle's actual inside diameter might be significantly different from the diameter stated on the label. For this reason it might be more economical to purchase nozzles slightly smaller than what you initially require.

Matching the Components of a Wet Abrasive Blasting System

The compressor, the blast hose and the blast nozzle must be matched, because taken together these three components affect the media consumption rate and the pressure. Selecting a nozzle with an inside diameter that is too small will not make full use of the blasting capacity. Conversely, selecting a nozzle that is too large will cause the pressure to decrease.

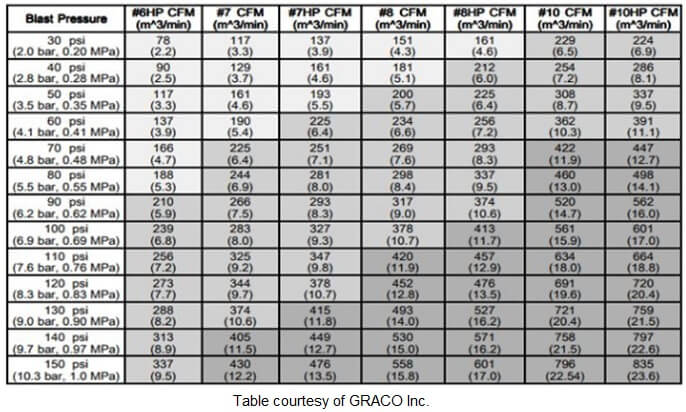

Keep in mind that the maximum abrasive media consumption rate does not always provide the best production rates and blasting efficiency. Furthermore, a high media consumption rate increases both the media cost and the cleanup cost. Manufacturers of blasting equipment often provide performance information to help select the right combination.

Pressure is determined by the water pump and a media flow control valve.

Table 3. Matrix for selecting the proper air compressor, blast pressure and nozzle size.

Finding the optimum blast pressure reduces costs and maximizes production efficiency when performing wet abrasive blast cleaning and surface preparation. This is a balancing act that entails taking into consideration the requirements of the job and the capabilities of the compressor, the blast hose and the blast nozzle.