For the better part of the past 30 years, composite repair technologies have been used to repair high-pressure pipeline systems around the world. In the early days of their use, these repair systems were primarily used to reinforce corrosion features.

However, through extensive research and testing efforts over the last 15 years, involving pipeline companies, composite repair technology companies, regulatory agencies, research organizations and subject matter experts, their use has extended to the reinforcement of dents, mechanical damage, vintage girth welds, pipe bends, seam welds and, more recently, leaking defects. Studies involving environmental and operational conditions have also been conducted to address elevated temperature conditions and subsea installations.

Joint Industry Programs (JIPs) have been instrumental in achieving widespread adoption of composite repair systems. Organizations such as the Pipeline Research Council International, Inc. (PRCI) have played a central role in evaluating composite repair technologies, including E-glass, carbon and even Kevlar fiber systems.

With standards such as ASME PCC-2 and ISO 24817, minimum design requirements for the composite repair industry have been established, bringing expected uniformity among at least ten internationally-recognized composite repair companies. (Read also: Designing and Testing a New ISO/ASTM-Compliant Composite Repair Solution)

The purpose of this article is to provide a brief examination of the benefits associated with using composite repair systems. Also included is a discussion on the development of a new composite repair product, the OmegaWrap™ system, which employs both E-glass and carbon fibers in an epoxy matrix.

Finally, a brief dialogue is provided to address current knowledge gaps and areas for future exploration regarding the use of composite reinforcing technologies.

Motivation

Having worked within the pipeline repair industry his entire adult life, Chip Edwards, fourth-generation president of Allan Edwards, Inc., recognized an opportunity that existed to enter into the terrain of composite repair technology.

He enlisted the help of Tommy Precht, an industry veteran with 25 years of experience in pipeline integrity. It was with that recognition that the OmegaWrap composite repair system was born. Chip and Tommy’s long and unique history with pipeline companies provided them a unique understanding of the critical role that customer service plays in offering a complete repair package.

With the help of ADV Integrity, Inc. (ADV) and its president, Dr. Chris Alexander, PE, development was planned and executed for both an E-glass-epoxy and carbon-epoxy version of the OmegaWrap repair system.

The following six months included a rigorous schedule of selecting, testing and evaluating different combinations of fabrics and resins before settling on the optimized configuration that is currently being introduced to the pipeline industry. Full-scale testing at the ADV test lab was conducted to validate the OmegaWrap composite technology.

Though steel repair sleeves are the “tried and true” method for repairing pipelines, composite repair technologies offer several unique advantages. First, composite materials that are installed “wet” can be used to reinforce a variety of pipe geometries and configurations, including wrinkle bends, elbows and branch connections.

The capability of conforming to pipe ovalities also cannot be discounted. Secondly, the flexibility to select different fiber types, fiber orientations and resins produces a wide range of technologies that can be used to reinforce everything from corrosion, which primarily requires “hoop” (circumferential) reinforcement, to wrinkle bends and girth welds that require axial reinforcement.

Lastly, with continued advances in fiber types and resins, there are numerous opportunities for expanded growth in the composite repair space. These advantages coupled with the ability to expand repair options beyond conventional steel sleeves made the development of the OmegaWrap composite repair system both an attractive and necessary investment. (Read also: Installation Methodology for Compliant Composite Repairs.)

Development of a Composite Repair System

As mentioned previously, the ASME PCC-2 and ISO 24817 standards have contributed significantly to the introduction of new and innovative composite repair technologies. Prior to the introduction of these standards, there were only a few companies offering composite repair technologies.

Since the acceptance and utilization of these new repair standards, however, the “barrier to entry” has been lowered, allowing new companies and technologies to be introduced to the marketplace.

The OmegaWrap composite repair system was developed using a very strategic approach. This involved not only identifying and testing different material combinations but also designing and conducting a testing program to better understand the performance capabilities of the OmegaWrap system.

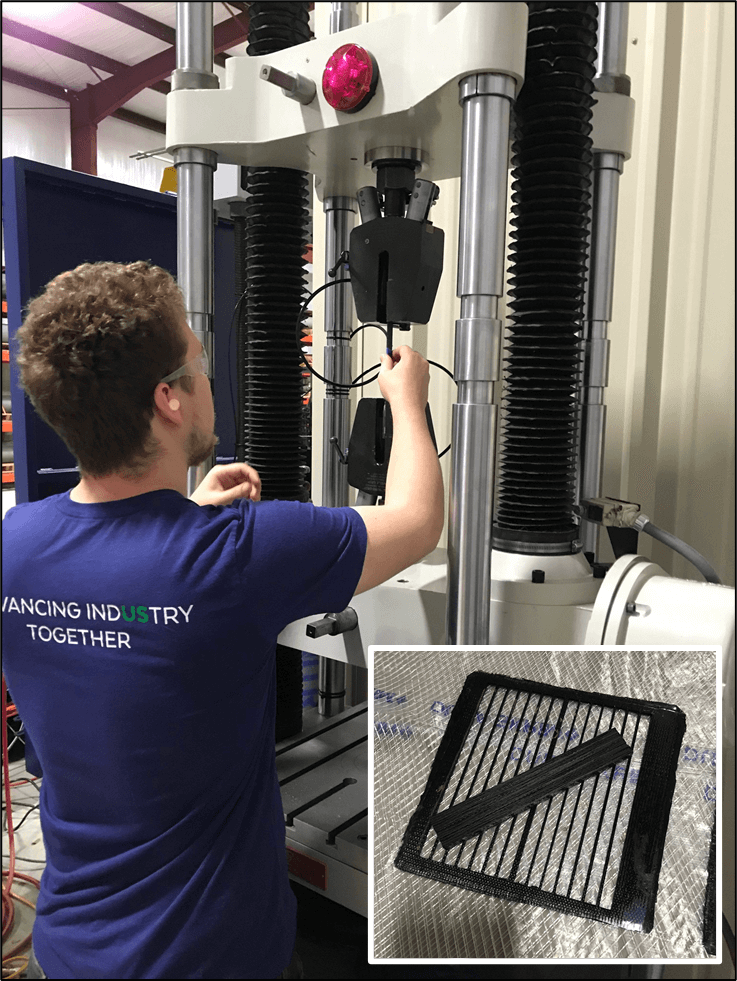

The most fundamental test in designing and qualifying a composite repair system involves fabricating panels and conducting tensile testing to determine the tensile strength, strain-to-failure and elastic modulus. Shown in Figure 1 is a photograph of a panel where the tensile coupons were extracted via water jetting, as well as a photograph showing one of the tensile samples being loaded in a tensile testing machine. (Read also: 6 Tests to Measure a Material's Strength.)

Figure 1: Tensile testing of a coupon extracted from a composite panel

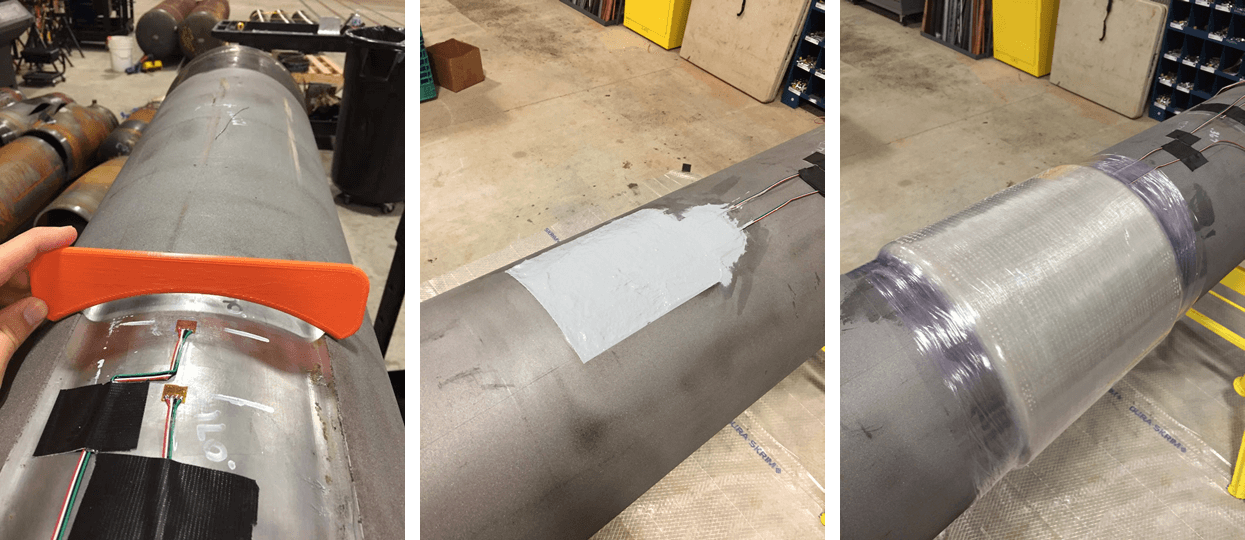

Depicted in Figure 2 is a series of photographs detailing the installation of the OmegaWrap E-glass system. Noted in these photographs is a pipe surface contour tool, printed with ADV’s 3D printer, that was used to ensure that an optimized contour of the load transfer material was achieved (as observed in the middle photo).

Figure 2: Photographs showing the installation of the OmegaWrap E-glass system

In addition to meeting the minimum requirements specified in ASME PCC-2, the OmegaWrap E-glass and carbon systems were subjected to testing to evaluate their performance in reinforcing dents, severe corrosion and cracks subjected to extreme cyclic pressure conditions.

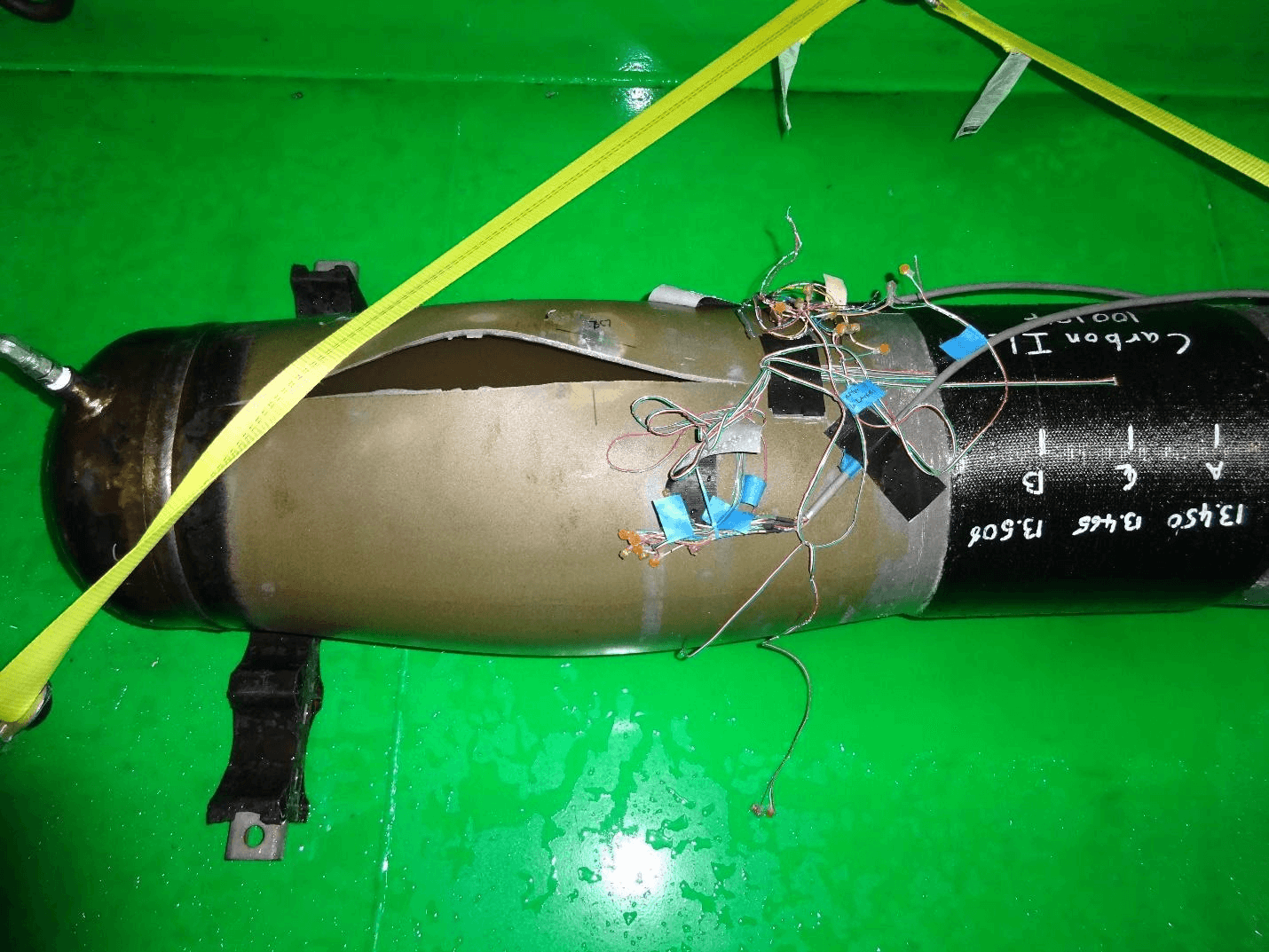

Burst testing was also conducted on test samples reinforced with the OmegaWrap carbon-epoxy technology, containing 15% and 50% EDM notch features that were pre-cycled to ensure cracking was present. The bullets below provide details of testing conducted on the 50% deep crack sample that was estimated to fail at 1,039 psig using the PRCI MAT-8 fracture mechanics software. The sample failed at 1,942 psig (157% SMYS) and failed outside the repair as shown in Figure 3.

- 12.75-inch x 0.188-inch, Grade X42 pipe.

- Crack dimensions: 3 inches long by 50% deep (0.094 inches).

- Fracture toughness of pipe: Kmat = 231 ksi in.

- Carbon epoxy system with a thickness of 0.33 inches (7 layers).

Figure 3: Post-test photo showing reinforcement of 50% crack feature

The Future of Composite Reinforcing Technologies

Because of the extensive assessment and world-wide use of composite materials, there is no doubt their use will continue and even expand in the coming years. With the innovative approach employed by oil and gas service companies, the composite repair industry will continue to advance existing repair systems and develop new technologies that meet challenging repair scenarios posed by pipeline operators. (Read also: What New Materials Science Studies Suggest About Corrosion Control in the Future.)

To ensure that tomorrow’s technologies are designed to meet these challenges, it is important to identify today’s knowledge gaps.

One area that will require continued development concerns the inspection of composite repair technologies. The role of inspection not only involves the technologies but requires that an assessment criterion be constructed against which feature measurements may be consistently measured. The ability to identify features such as interlaminar delamination and pipe-to-composite disbondment are only meaningful when they are compared to values identified as either “acceptable” or “unacceptable.”

Another area that requires continued development involves validation associated with pipeline operation, namely elevated temperature conditions and aggressive pressure cycling. Fortunately, previous testing programs have demonstrated that certain composite repair technologies exist that can meet these demands. However, additional work is required to achieve widespread acceptance and adoption.

The future use of composite repair technologies is promising, and their numerous uses will undoubtedly continue to expand dramatically. The key to ensuring long-term progress involves the forward-thinking mindset of companies and their willingness to invest time, capital and resources into developing new and improved technologies, coupled with validation through numerical modeling and full-scale testing.

The ultimate goal is to ensure that the performance capabilities of a composite repair technology meet and exceed the rigorous demands of integrity programs managed by pipeline companies around the world – continually refining today’s technology to meet tomorrow’s needs.

Editor's Note: This article was written by Allan “Chip” Edwards and Tommy Precht. Please see their author bios below.