There is no shortage of options when it comes to concrete floor coatings. These materials are generally used to protect underlying concrete floors from wear as well as prevent the corrosion of steel reinforcement. (To learn more about the specifics corrosion in reinforced concrete, see Corrosion Resistance in Reinforced Concrete Structures.) In many cases, floor coatings can also be used to:

- Decorate floors by brightening or defining certain areas of the facility

- Mark traffic isles

- Route traffic

- Cover stained concrete

In this article we will look at some of the most commonly specified concrete floor protective coatings and give an overview of some of their advantages, disadvantages and typical applications.

Epoxy Floor Coatings

Epoxy floor coating systems are made up of two distinct elements: an epoxy resin and a polyamine hardener. These two components are mixed prior to application. When the resin and the hardener are combined, they engage in a chemical reaction that creates cross-linking of the elements as it cures. The result of the chemical reaction is a hardened, rigid plastic coating material that bonds well to most base layers.

Epoxy floor coatings are known for their hardness, durability and impact resistance. These characteristics make epoxy coatings ideal for heavy-duty applications such as industrial facilities, warehouses, logistic centers and other areas that may be subjected to heavy forklift traffic. Epoxy is also known for its resistance to chemical products, such as bleach, oils, greases, cleaners, etc. This chemical resistance makes them a popular choice in garages in the automotive industry.

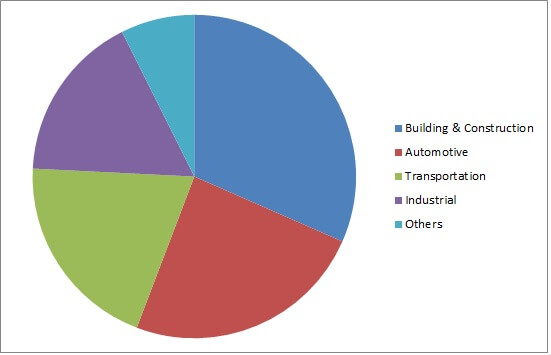

Figure 1. Epoxy coatings market, revenue (%), by end-user industry, global, 2018.

One of the main disadvantages of epoxy floor coatings is its difficult application process. Surface preparation, in particular, can be tedious. Epoxy flooring cannot be applied to contaminated, damaged or unprepared surfaces. To ensure coating longevity, the floor must be free of any grease, oils or solvents. Damaged surfaces must also be repaired, and the concrete may need to be ground to open up its pores and profile the surface. (Learn more about this procedure in 6 Ways to Measure Surface Profiles for Concrete Surface Preparation.) Additionally, this material takes approximately seven days to cure; therefore, epoxy floors have a significantly slower turnover time than other coatings.

Polyurethane Floor Coatings

Polyurethanes are polymers that are connected to a chemical compound group known as carbamates. Polyurethane is a thermosetting polymer by nature; i.e., it does not melt when heated. To the untrained eye, polyurethane coatings may appear to be visually similar to epoxy coated floors. However, they possess distinct characteristics that make them ideal for specific applications.

Unlike epoxy coatings, which are highly stiff and impact-resistant, polyurethane floor coatings are relatively softer and more elastic. This attribute makes polyurethane floor coatings better suited for areas with moderate to heavy pedestrian traffic. The increased elasticity also makes polyurethane-coated floors more resistant to abrasion, since impact loads are easily absorbed and less prone to cause scratches. The elasticity and flexibility of polyurethane also contribute to their ability to operate in environments with low freezing temperatures.

The desirable characteristics of polyurethane floor coatings make them ideal for several applications, including car parks, freezing chambers and busy commercial facilities, such as shopping malls, airports and hospitals.

One of the other significant advantages of polyurethane floor coatings is their curing time. Floors coated with this material can be ready for operation the next day. In contrast, epoxy coatings need at least seven days to cure before they can be ready for use.

While polyurethane possesses many beneficial properties, they do have a few shortcomings. Firstly, polyurethane floors are highly sensitive to moisture. When moisture attacks the floor, bubbles can form on the surface, causing unsightly blemishes on the surface. Polyurethane floor coatings are, therefore, not recommended for use in areas with high levels of humidity. Their limited pot life and moisture sensitivity also make them challenging to work with. As such, the proper handling and application of polyurethane coatings usually require well-trained and knowledgeable staff.

Polyaspartic Floor Coatings

Polyaspartic is a subset of polyurea. (More information about polyurea coatings can be found in the article The History and Industry Adoption of Polyurea Coating Systems.) Like polyurea floor coatings, polyaspartic is a two-part system, i.e., the resin needs to be combined with a catalyst to facilitate the curing and hardening process. While early variations of polyaspartic floor coatings possessed several shortcomings, innovations in coating technology have made these floor coatings a versatile alternative to epoxy and polyurethane coating systems.

One of the primary benefits of polyaspartic is its ability to be used as a complete flooring system as well as a topcoat. In other words, polyaspartic floor coatings can achieve in a single coat what traditional epoxy and polyurethane would normally take two coats to accomplish. As a result, polyaspartics can significantly reduce application times, labor and material costs.

Another benefit of polyaspartic floor coatings is its ability to be customized. Polyaspartic esters can be manipulated to control drying times and pot life. This characteristic lessens lag time and allows assets to be put back into service faster. Some coating formulations can dry in a matter of hours, with a next-day return to service.

Because polyaspartic floor coatings meet or exceed some of the properties of their polyurethane counterparts, they can be used in many of the same applications. These primarily include areas with medium to heavy foot traffic, such as airports, malls, shopping centers, hospitals, etc.

Similar to epoxies, polyaspartic floor coatings require careful attention to surface preparation. Improperly prepared surfaces can result in various types of coating failure. Also, while polyaspartic coatings with 100% solids have low volatile organic compound (VOC) emission rates, most polyaspartics are solvent-based. These solvent-based coatings can be dangerous to inhale; therefore, skilled labor and appropriate respiratory equipment are required during application.

Acrylic Floor Coatings

Most acrylic floor coatings are made with more than one monomer, such as ethyl acrylate, methyl methacrylate or butyl acrylate. These components are often processed in a solvent, usually water. These floor coatings offer a middle ground in terms of cost and performance.

Acrylic floor coatings are not as durable as their epoxy or polyurethane counterparts. As such, they may need to be buffed or recoated more frequently than other coatings. Therefore, while the initial cost of acrylic floor coatings may be relatively inexpensive, long-term maintenance costs tend to be higher than those for other coatings.

Due to these shortcomings, acrylic floor coatings are best suited for decorative concrete, surfaces with minimal foot traffic, and areas with minimal risk of abrasions or chemical spills. Specific acrylic formulations, however, can offer superior performance characteristics, such as enhanced UV protection, slip resistance and water resistance.

While acrylic lacks the durability of other floor coatings, they possess relatively fast curing times, drying as fast as an hour after application. This reduces the overall labor requirements and turnaround times. Additionally, the surface of the coating can be easily buffed in the event the coating becomes damaged during operation.

Conclusion

Concrete floor coatings offer unique properties and benefits that lend themselves to various applications. Several factors, such as anticipated traffic, environmental conditions and durability requirements, must be carefully taken into consideration to determine which concrete floor coating product is most appropriate a specific project.