What Does

Proof Stress Mean?

The proof stress of a material is defined as the amount of stress it can endure until it undergoes a relatively small amount of plastic deformation. Specifically, proof stress is the point at which the material exhibits 0.2% of plastic deformation.

This type of stress is typically used in the manufacturing industry to ensure that a material is not stressed far beyond its elastic limit. That is, a safe load is applied such that the object is not stressed to the point where it irreversibly changes in size or shape. If a material is allowed to exceed its proof stress, it can deform permanently, and failure or fracture can ultimately occur.

Proof stress is particularly useful in the marine and offshore industries. The proof stress of ships and platform legs plays an important role in determining how much force these structures can take before they become permanently deformed.

Proof stress is also known as offset stress because it is the stress required to make the material yield.

Corrosionpedia Explains Proof Stress

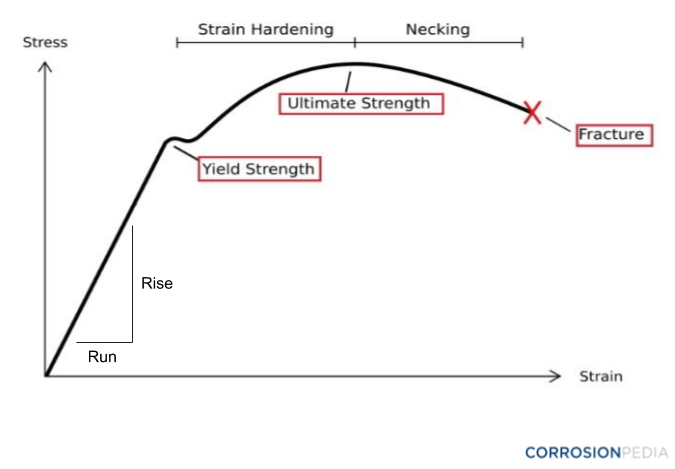

Proof stress is usually calculated for metals that do not have a properly defined yield strength. For example, consider the stress-strain graph below for low carbon steel. The graph has a distinct shape where the yield stress is easily identifiable. The distinct “kink” in the graph shows the point where the material yields, i.e., it no longer acts as an elastic material as it transitions into the plastic range of the curve.

Figure 1. Typical stress-strain graph of ductile low-carbon steels.

In other words, beyond the yield point, if the force is released from the object it will experience permanent deformation and no longer return to its original shape. Therefore, the yield point is an approximate estimate of the elastic limit of the material. In this case, we simply project a horizontal line from the yield point to the y-axis of the stress-strain curve to get the value of the yield stress.

However, in some other steels determining the yield stress graphically is not as straightforward. For example, non-low-carbon steels and some non-ferrous steels such as copper, brass and aluminum have no definitive yield point. That is, there is no “kink” in the graph that shows a clearly defined yield point. Rather, the straight-line portion of the graph (the elastic zone) gradually transitions to a non-linear curve. This blurred transition from the elastic zone to the plastic zone makes identifying the yield stress less difficult.

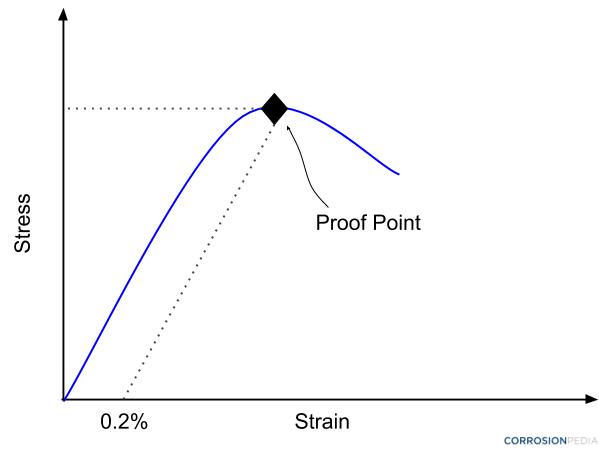

Since the yield point or yield stress is not obvious, proof stress is used. This gives a stress value that will produce a very small amount of known plastic deformation. By keeping a material below its proof stress, we can ensure that parts and components can be used safely in their application even though the exact yield value may not be known.

How Proof Stress is Calculated

Proof stress is determined using a tensile test. A cylindrically-shaped test specimen is placed in an apparatus and clamped at both ends. One end remains fixed while a tensile axial load is applied to the other. The stress and strain in the sample are measured, recorded and plotted on a stress-strain graph. A straight line offset at 0.2% strain is extended parallel to the linear portion of the graph until it meets the stress-strain curve. The stress at the intersection between this line and the curve is the value of the proof stress.

Figure 2. Procedure for calculating proof stress.