What Does

Minimum Closure Force Mean?

Minimum closure force is the pressure required to break through corrosive and oxide films to make a low-resistance contact. It is the minimum compression which is necessary to obtain corrosion-resistant joints.

A minimum closure force is recommended to obtain low surface contact resistivity and good shielding. Minimum closure force is very important in sealant applications such as gaskets.

The minimum closure force provides an excellent seal against light, dust and water in mechanically fastened assemblies.

Corrosionpedia Explains Minimum Closure Force

In closure applications, minimum closure forces are required to provide high shielding effectiveness. Gaskets are used for this purpose. A minimum force should be applied on the gasket to establish good shielding effectiveness. Maximum closure force is recommended on two criteria: maximum compression set of 10%, and avoidance of possible damage to the gasket material when pressure exceeds the recommended maximum.

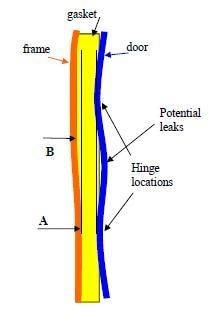

In order to seal using a gasket, it must exert some force on the surfaces to be sealed. The force the gasket exerts on the door is generated by compressing the gasket. This force is proportional to the compression; therefore the force varies along the gasket. This compression force bends the door. This can be seen in the following figure:

A – Maximum force

B – Minimum force

While a target compression or closure force of 30% is ideal for most sealing applications, a range of 30% to 60% compression is adequate for many uses. A tape thickness of 1.4 to 2.5 times the joint gap assures a positive seal. For sound, light and dust seals, 15% compression may be acceptable.

Low-closure force seals reduce bolt loading and flange requirements when sealing enclosures and boxes. This reduced closure force is achieved by changing from a solid to a hollow cross-section without lowering the material hardness.