The sheer numbers of things that can go wrong when applying a protective coating to a valuable asset are seemingly endless. Some problems may be due to poor technique or selecting an inappropriate product. Others, including the five highlighted in this article, can be avoided by adhering to the coating specifications provided by the manufacturer or specifications writer. (You can learn more about specifications in the article Coatings Specifications, Good, Bad or Ugly: Lou Vincent Q&A.) Although there is some leeway for site-specific variations, it only makes sense to faithfully follow the coating specs considering the amount of effort that went into writing them in the first place.

Adhesion Failure

Description

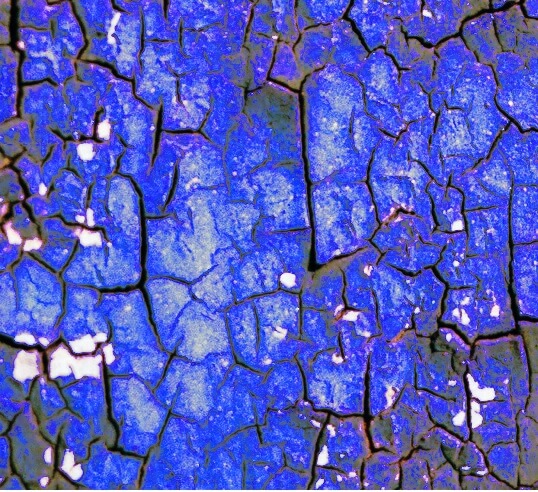

An adhesion failure appears as a paint that is flaking off because it failed to stick to either the substrate or a prior coating (if there was one). It can be caused by surface contamination, condensation on the substrate, applying two different coating products that are incompatible or by exceeding the overcoating time. There are two types of adhesion failure: intercoat adhesion failure and substrate adhesion failure.

Figure 1. Intercoat adhesion failure (Dmitry Guzhanin / Dreamstime.com).

Other coating failures are sometimes mistakenly called adhesion failures, but strictly speaking these are not a proper use of the term. An adhesion failure occurs when the chemical bond is broken between the coating and the substrate at the bonding interface. To be a true adhesion failure, the bond must not be broken due to other conditions such as abrasion, impact or underlying corrosion.

Prevention Methods

Ensure a good anchor pattern exists on the substrate, and if needed increase the surface profile by sanding or abrasive blasting.

Next, the surface to be coated must be properly prepared so that it is free of moisture, dust, dirt, old coatings or any other contaminants such as grease, wax or oil.

Follow the manufacturer’s guidelines and apply secondary coatings only during the specified time window.

Allow the coating to properly cure according to the manufacturer’s recommendations.

Alligatoring (Crocodiling)

Description

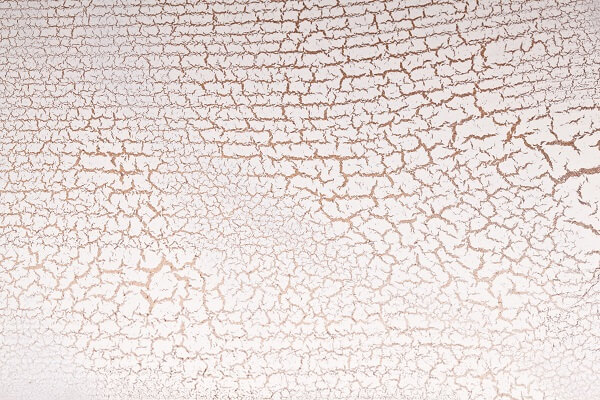

Alligatoring, also known as crocodiling, appears as large cracks or crazing that looks like the scales on an alligator or crocodile. The cracks usually do not penetrate down to the substrate.

This defect occurs when the upper surface of the coating shrinks faster than the portion of the coating (the body of the coating) that is closer to the substrate. The unequal shrinking creates stresses that pull on the surface differently than within the body of the coating.

Figure 2. Alligatoring (crocodiling) coating defect (Ag042d / Dreamstime.com).

Alligatoring may be caused by a coating that does not have enough flexibility when the temperature changes, by applying the coating with a greater than recommended thickness, by using an inflexible hard top coat over a more flexible soft undercoat, or by not allowing sufficient time for the undercoat to dry before applying a subsequent coat or top coat. It can also be caused by heating the finished piece (e.g., in an oven) to accelerate drying.

Prevention Methods

Before starting, ensure all the coatings in a multi-layer system are compatible. Select a coating that is more flexible or that contains reinforcing fibers or pigments.

Follow the manufacturer’s guidelines and perform the coating application when the ambient temperature is steady and not too hot. Avoid extreme temperature variations.

Do not permit excessive film thickness during the coating process, and allow the primer or basecoat to dry completely before applying the top coat.

Crazing

Description

Crazing presents itself as a network of wide cracks on the coating’s surface that may or may not penetrate to the substrate. In a general sense, crazing is caused by tension within the coating. Specific causes include attempting to apply the coating in cold ambient temperature conditions, applying two different coating products that are incompatible, or by applying the coating with an excessive film thickness.

Figure 3. Crazing coating defect (Valentyn75 / Dreamstime.com).

Crazing is common with acrylic paints that develop a skin when drying while the portion of the coating closer to the substrate (the body of the coating) is still liquid.

Prevention Methods

First, ensure all the coatings in a multi-layer system are compatible. Follow the manufacturer’s recommendations regarding temperature. If outdoors, perform the work only when the drying conditions are appropriate for the coating. Avoid extreme atmospheric variations or cold temperatures. (For more on this subject, see Tightrope: Identifying Limiting Conditions for Coatings Specification.)

Apply the coating thinly and avoid thicker sections or puddles. Several thinner coats are better than one thick coat.

Undercutting

Description

Undercutting appears as a coating that flakes or peels off around corroded portions of the substrate. At this point the asset is in jeopardy because not only is there a coating problem, there is also a (previously hidden) corrosion problem.

Undercutting occurs when corrosion forms on a metal substrate beneath a coating. The corrosion products lift the protective coating up and away from the substrate, allowing moisture and salts to reach more areas of the substrate, thus facilitating more corrosion as it creeps along the surface to dislodge the coating.

Figure 4. Undercutting caused by corrosion products forming on a metal pipe (Felix Bensman / Dreamstime.com).

Undercutting is caused by applying a coating to a surface that is already corroded without first performing proper surface preparation. The root cause of the insufficient surface preparation or inadequate/improper coating application is often because the location is hard to reach, which makes inspection and remediation difficult.

Undercutting is common when a coating is applied over mill scale, which in the presence of water and oxygen reacts to cause a loss of adhesion and progressive corrosion.

Less frequently, it may be caused by an incompatibility between the coating and the substrate.

Prevention Methods

Ideally, improve the asset’s design or access. Perform proper maintenance procedures throughout the service life of the asset to avoid corrosion in locations that will be difficult to rectify later.

Perform proper surface preparation (e.g., abrasive blasting or water jetting and cleaning) before applying the coating. The substrate’s surface must be free of old corrosion products.

Consider an inorganic zinc or other suitable primer.

Finally, select a coating with very good adhesion characteristics.

Wrinkling

Description

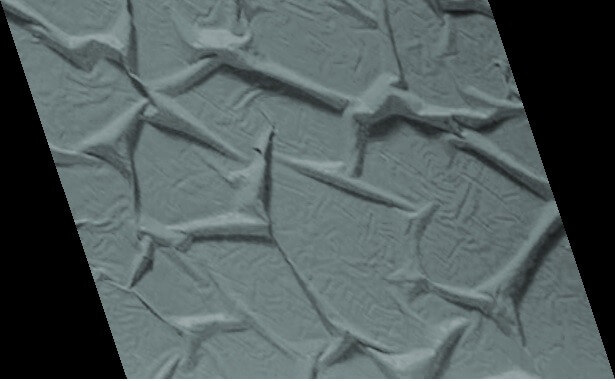

Wrinkling appears as wrinkles in the coating film while it is drying. The coating’s surface may look like a piece of cloth or plastic film with furrows and ridges, or like a diamond-patterned steel floor (although not in a regular pattern).

Figure 5. Wrinkling coating defect appears as ridges and furrows (Ewelina Banaszak / Dreamstime.com)

Wrinkling is initiated when a skin quickly forms on the coating’s surface while the body of the coating that is closer to the substrate remains liquid.

Wrinkling has many possible causes, including improper mixing of components (especially with oil-based coatings or alkyds that contain driers), not allowing sufficient time for the undercoat to dry before applying a subsequent coat or top coat, applying the coating with a too-high film thickness (this is especially common with alkyd coatings), or applying the coating in hot ambient temperature or high humidity conditions.

Baking the object at too high of a temperature will cause the coating’s surface to cure faster than the body of the coating and lead to wrinkling.

Wrinkling may also be caused by applying the coating over wax or grease.

Prevention Methods

Use a wax and grease remover to wash away these contaminants before coating.

Select an appropriate coating system and follow the manufacturer’s recommendations regarding environmental limitations and compatibility of the primers and paints. Follow any instructions regarding formulating/mixing of the components.

Apply the coating thinly and avoid thicker sections or puddles. Use several coats if necessary.

Conclusion

Avoiding these coating defects are necessary to produce a protective coating with a long service life. Fortunately, adherence to the coating specs takes a lot of guesswork out of the equation, or at least can help you understand what went wrong when you find yourself with a coating failure.