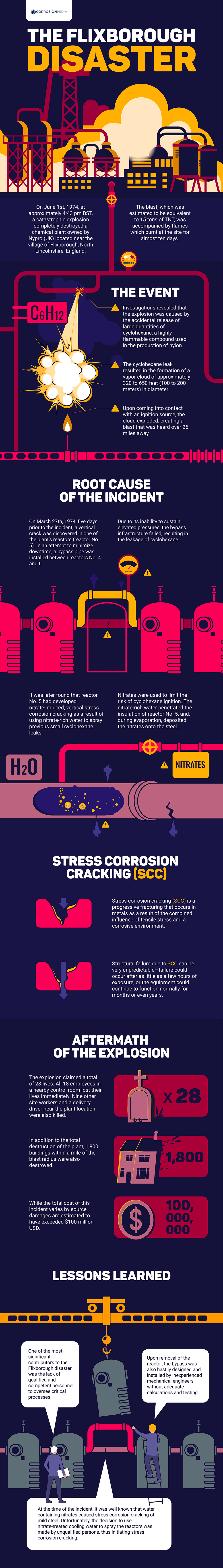

In 1974, a chemical plant in Flixborough, England exploded, resulting in multiple deaths and millions of dollars in damages. This disaster could have been prevented, if more qualified persons, with corrosion failure experience, had been present.

Most corrosion failures are not unique. For the majority of failures, a similar failure has occurred in the past. It is up to the experts to conduct failure analyses and to use the history of corrosion failures to help prevent similar failures from happening in the future. (Learn more in The 3 Stages of Corrosion Failure Analysis.)

But, what if those experts aren't present?

In 1974, a chemical plant in Flixborough, England exploded, resulting in multiple deaths and millions of dollars in damages. The explosion was a result of stress corrosion cracking (SCC) caused by using nitrate-rich water to spray leaks in the reactors. Moreover, this disaster occurred due to inexperienced and unqualified persons making important decisions.

The infographic below takes a look at the cause and aftermath of the disaster, and how the explosion could have been prevented.

Share this Image On Your Site