Regular and planned asset maintenance is vital for reinforced concrete structures. Such maintenance should not be a "cosmetic repair" but rather a proper root cause analysis that must be carried out to identify and understand the actual source of the problem. Material selection is an important step in asset maintenance and refurbishment projects though only after the root cause has been addressed. Conducting proper root cause analysis in restoration and refurbishment projects will prevent one from falling into a vicious cycle of "repairing the repair". A study conducted by Jingmond and Ågren (2015) has highlighted the importance to look at the root causes of the defects in concrete from the organizational perspective as well, instead of only at the operational level. (For more on analyzing failures, read The 3 Stages of Corrosion Failure Analysis.)

Multifactorial Reasons for Concrete Failures

A defect or problem in an existing reinforced concrete structure is multifactorial; it often stems from obscure reasons. Like the cause of a common headache that is often attributed to a pathological cause leading to expensive and often needless investigations and treatments, whereas, the actual cause may be a stress triggered tension headache. Similarly, stomach infections are common during monsoons in Asia, which are due to the 100 year old corroded sewage pipes leaking into the parallel running municipal water pipes. A point to ponder here is whether treating the gastro patients with medicine or changing water filters would make the situation better without addressing the root cause of the problem?

Concrete Cracking

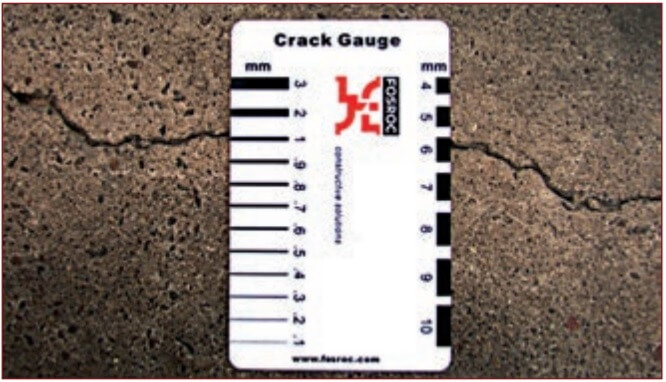

Corrosion of steel generates iron oxides and hydroxides, resulting in the increase of volume 5 to 8 times of its original size. This increase in volume causes expansive forces to accumulate within the concrete around reinforcement and results in cracking and in areas with low cover, concrete spalling. Cracks provide easier access to oxygen, moisture, chlorides and other corrosive agents that create conditions suitable for accelerating the electrochemical corrosion process. Pretensioned concrete bridge girders may exhibit unexpected end cracking upon pre-stress release. These cracks may propagate into the bottom flange of the girder where strands are located and can increase in width with increased traffic loads. Leakage from the bridge expansion joint could penetrate the bottom flange cracks and trigger severe corrosion. In this case expansion joint leakage must be arrested prior to the crack and concrete repair activity.

Figure 1. Concrete cracks provide easy access to corrosive agents.

A common form of cracking at an early age on new concrete decks is known as transverse cracking which may appear over the length of span above transverse reinforcement. These cracks can accelerate corrosion rates, reduce the service life of the asset and increase maintenance costs. When a mass of concrete that shrinks as it ages is restrained, cracks will occur. For example, restraint of a concrete deck by an integral support girder against its volume change initiates cracking. Multiple factors such as concrete materials and mix design, ambient temperature changes, humidity, bridge design characteristics and construction practices can all contribute to volume change and/or to degree of restraint of concrete mass. However transverse cracking cannot be attributed to all of the above factors. It is therefore important to identify the major contributing factor(s) to address the root cause of cracking.

A crude approach while examining the corrosion induced damage in bridge structures, particularly in the marine environment, is to assume the presence of chlorides as the main cause of failure. Chlorides might be the reason for corrosion but not the actual cause of the bridge defect. The root cause of failure of the bridge structure cannot be simply corrosion. There are many factors involved that could lead to corrosion and ultimately lead to failure of the bridge, such as cracks in bridge girder web and flange, poor bridge drainage system, failed bridge deck waterproofing membrane, inappropriate bridge joints, void in the prestressed or post tensioned cable ducts due to excessive grout bleed. Other factors at macro level are related to design, material, environment and construction practices. It is important to address the main contributing factor(s) of the defects in bridge structures affected by corrosion. (For further reading, see Correcting and Preventing Concrete Corrosion.)

Figure 2. Linear transverse cracks on new bridge deck due to plastic shrinkage.

It is quite common to observe a local white patch of efflorescence that appears like a chalky powder at ground floors due to rising or penetrating dampness inside institutional buildings, hotels and residential apartment buildings. This phenomenon occurs due to a number of factors. For example, one of the factors is the absence of or damage to the damp-proof course which allows entry of moisture from the ground below, or from unsealed landscape planters outside hotel rooms, which seep through the external walls and result in white patches of dampness along the perimeter of the internal wall. Treating the damp patch from inside would only solve the problem temporarily as it could recur unless the damp-proof course is repaired.

Figure 3. Surface grinding to open the face of the crack and sealing with epoxy resin.

Effective Repairs Require an Understanding of the Root Cause of Corrosion

Concrete repairs conducted without considering the actual source are cosmetic repairs and may last only for few months. For instance, repairing the spalled concrete of a balcony with quick-fix patch method, even applying the best quality repair mortar, would not solve the problem unless the root cause has been identified and addressed. It could be attributed to more than one cause such as leakage due to failure of a waterproofing membrane, a broken drain pipe, leaking concealed pipe joints or a combination of these factors. Corrosion of reinforcement that has caused spalling of balcony is not the root cause here. (For more on root cause analysis, see 6 Ways to Prevent Corrosion Failure Analysis Frustration.)

Figure 4. Cathodic protection to bridge piers affected by cracks, corrosion and spalled concrete.

Roof leakages in buildings result in seepage into the rooms below. This causes discomfort to the occupants and frequent disputes between the landlord and the tenant in regard to the liability for repair.

The failure of roof waterproofing is often attributed to poor workmanship. Based on this notion, the roof refurbishment is carried out but the leaks appear again after some period of time. Research conducted by Lo, Leung and Cui (2005), on roof construction defects have highlighted that the root cause of failure of the roof waterproofing membrane stems from the roof parapet wall cracks. It further concluded that the design and choice of material for a roof parapet wall is critical to avoid waterproofing membrane failures on the roof slab. Other reasons for roof leakage could be wrong termination details of the waterproofing membrane at up-stands and drains, improper selection of the waterproofing system and poor roof joint detailing.

External tiles falling from the building façades can cause damage to assets and pose a potential safety hazard to pedestrians. The number of casualties and injuries caused by the failures of external wall finishes is a serious concern to the authorities in many countries. Ho, Lo and Yiu (2005), in their research highlighted various factors that could lead to external tile failures such as thermal and moisture effects that induce movement of tiles, inferior quality adhesive, poor workmanship, improper joints, weathering, vibration and substrate properties. The failure could be due to a single factor or it could be the effect of a combination of the above factors. It is therefore vital to recognize and address all the major contributing factors of the de-bonding and falling of tiles.

Figure 5. Repair of balcony concrete corrosion and spalling due to multiple factors.

Conclusion

Finding the real cause of a concrete problem rather than merely dealing with its symptoms is the key to success for a durable repair and refurbishment project. Aspirin quick-fix approach in handling concrete defects may only provide a temporary cosmetic solution. The aim of this article is to create an awareness among the civil contractors and engineers that to solve the concrete defects effectively, they need to drill down through the symptoms to establish the actual root cause. Reexamining, re-designing, re-assessing, re-selecting, re-applying and lots of "re-s", can easily be avoided by examining and fixing the root cause of the concrete defect to ensure the same problems are not recurring.