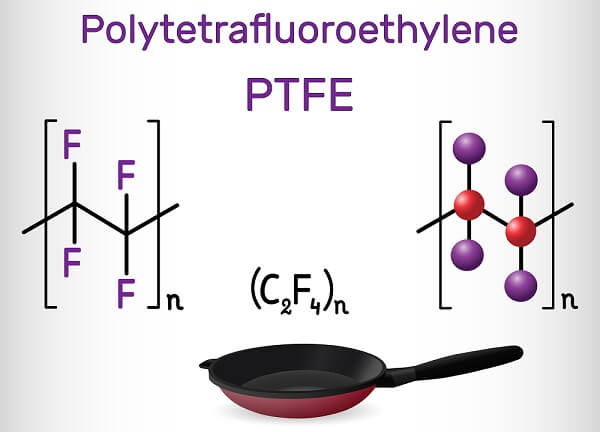

Xylan is an industrial dry film lubricant consisting primarily of one or more fluoropolymers including polytetrafluoroethylene (PTFE) (Figure 1), perfluoroalkoxy alkane (PFA) and fluorinated ethylene propylene (FEP). This coating is generally used to reduce friction, improve wear resistance and create non-stick surfaces. However, one of the main uses of Xylan coatings in industrial applications is for corrosion resistance. Xylan coatings are commonly used to protect a variety of parts and components in the automotive, construction and oil and gas industry to name a few.

Figure 1. Molecular structure of polytetrafluoroethylene (PTFE), a fluoropolymer commonly found in Xylan coatings.

Xylan coatings are available in a variety of formulations, each with physical and mechanical properties that lend themselves to different situations. Selection of the best Xylan coating depends on the desired level of lubrication, temperature resistance, corrosion resistance and abrasion resistance required by the specific application.

Some of the most common types of Xylan coatings, their properties and appropriate uses are listed below:

Xylan 1424 – Xylan 1424 is a water-resistant, low-friction coating with relatively high resistance to abrasion, chemical degradation and corrosion. These attributes make Xylan 1424 especially ideal for caustic environments. This type of coating is also VOC-compliant for environmentally sensitive and sustainable applications.

Xylan 1070 – Like Xylan 1424, Xylan 1070 is water-resistant, has a low coefficient of friction, and also possesses formidable corrosion and heat resistance. This PTFE coating is ideal for leak prevention in tanks, vessels and valves operating in relatively aggressive environments. (For more information on protecting process vessels, read Introduction to Managing Internal Corrosion in Process Vessels.)

Xylan 1010 – Xylan 1010 is a specially formulated PTFE lubricant renowned for its abrasion resistance and ability to operate in environments with temperatures up to 550°F (288°C). Like other Xylan coatings, Xylan 1010 also possesses a low coefficient of friction, allowing it to be used on almost any wear surface.

Xylan 1014 – Similar to Xylan 1010, Xylan 1014 is also a low-friction lubricant; however this coating formulation contains a significantly higher percentage of bonding resins. This makes Xylan 1014 less porous and more abrasive resistant than its counterparts are. Xylan 1014 is also capable of producing an aesthetically pleasing, glossy finish.

Xylan 1052 – Like Xylan 1010, Xylan 1052 is a dry film lubricant with the ability to withstand extreme temperatures up to 550°F (288°C). This coating can also maintain its stability in high-pressure environments and possesses strong binding lubrication for low-speed wear applications.

Xylan 1425 – Xylan 1425 also possesses substantial heat resistance (up to 400°F/204°C), albeit less than its 1052 and 1010 counterparts. Xylan 1425 is water and chemical resistant and is suitable for high-pressure, low-speed applications.