Minimizing performance deterioration of equipment is an important factor for pump manufacturers and end users in the water and energy industries. Indeed, hydraulic losses account for most of the decreases in efficiency experienced by pumping systems—commonly 9% reduced efficiency in mixed flow pumps, and 20% in radial flow pumps.

Fluid handling equipment may suffer from multiple problems, including physical and mechanical damage, as well as general or localized erosion and corrosion. (Background reading: Understanding Corrosion in Pumps and How to Deal With It.) These problems are linked to decreased efficiency and poor performance, which in turn increase operational costs. Certain new coating technologies are helping to control these losses by increasing pump performance.

Smoother Surface, Less Friction

In pumping equipment, it is possible to reduce power consumption and improve hydraulic properties by changing the pump surface finish. Loss of pump efficiency is caused by:

- Frictional forces created between the fluid and the walls

- Acceleration and slowing down of the fluid

- Changes in fluid flow direction

The smoother the pump walls are, the more fluid turbulence will be reduced, thus reducing the energy required for the pump to move fluid through the hydraulic passage.

In order to get the best performance possible, pump manufacturers seek to create the smoothest surface possible to reduce fluid turbulence. This can be achieved by polishing the metal, such as stainless steel. However, this method is extremely time-consuming and expensive. A smooth surface finish can also be obtained by applying an erosion-corrosion resistant efficiency coating on the pump volute and impeller. Polymeric coatings are specifically designed to improve efficiency on fluid handling systems and protect metals against the effects of erosion corrosion. (Note, however, that polymeric materials are not corrosion-proof, as discussed in the article The Corrosion of Polymeric Materials.)

Testing Smoothness & Efficiency

Unique properties such as self-leveling application, hydrophobicity and hydraulic smoothness make these coatings ideal candidates for lining the hydraulic passages of pumps. The unique coatings possess a low electronic affinity toward water molecules, resulting in a smooth glossy finish. Water or other aqueous solutions slide easily over the coating surface.

The level of smoothness is demonstrated in Graph 1 below. The surface condition of a high-performance coating designed to improve the efficiency of pumps, pipes, valves and other fluid handling equipment (Belzona 1341 Supermetalglide) was measured as 15 times smoother than polished stainless steel.

Graph 1. Surface smoothness comparison between polished stainless steel and Belzona 1341.

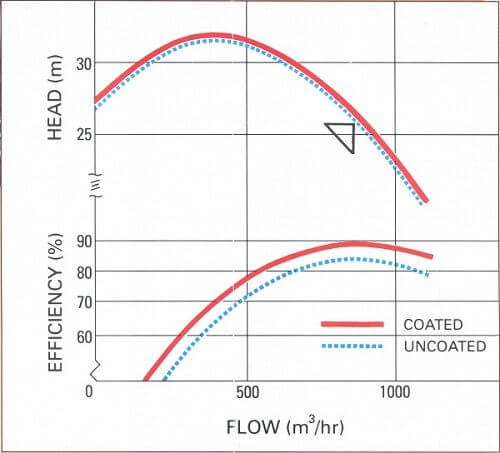

As a result of the smoother surface and reduction in flow resistance and friction, the hydraulic performance of the pump can be increased. Graph 2 shows the performance curves of a single stage, end suction centrifugal pump with 250 mm suction and discharge branches, before and after being coated with Belzona 1341.

Graph 2. Performance curve of a new pump before and after coating with Belzona 1341.

This test was performed by the British National Engineering Laboratories (N.E.L.). The pump, in uncoated condition and running at 1,300 rpm, was originally found to deliver 875 m3/h at 26.5 meters head, and with overall peak efficiency of 83.5% (overall efficiency defined as the ratio of water power output to mechanical power input at the shaft).

Testing of the Belzona 1341 coated pump gave a maximum of 6% increase in the peak efficiency and a reduction in power consumption of 5.1 kWh at duty point. Assuming a 5,000 hours operating cycle per annum, the power savings over this period would amount to 25,500 kWh.

Case Study: Water Elevation Plant

In 2013, a water elevation plant in Portugal was looking for a solution to improve its hydraulic efficiency. This plant was chosen because of its high energy consumption and costs, with an annual consumption of 1.7 GWh/year and a volume of water propelled of 1.2 Mm3/year recorded in 2012.

Figure 1. Corroded pump impeller before repair and surface preparation.

Figure 1. Corroded pump impeller before repair and surface preparation.

The client was looking for a reliable long-term solution to restore the damaged pump while reducing internal friction in the impeller and volute to enhance hydraulic efficiency. An internal pump coating was selected to maximize water flow, reduce energy consumption and internal wear, and minimize future maintenance actions.

Figure 2. Pump impeller repaired and coated.

Figure 2. Pump impeller repaired and coated.

The pump was disassembled and all internal surfaces were grit blasted to remove the previous coating, creating a substrate cleanliness of at least SA2,5 and a surface profile of at least 75 µ. The surface was then cleaned and inspected to ensure that it was free of dust and other particles.

Figure 3. Pump before application.

Figure 3. Pump before application.

Areas were masked for application of an epoxy paste grade composite metal repair (Belzona 1111 Super Metal). Applied using an applicator provided with the product, the epoxy material was used to reconstruct areas damaged by corrosion, rebuilding the original surface profile. This solvent-free composite creates a corrosion and abrasion-resistant surface.

Figure 4. Belzona 1341 Supermetalglide applied.

Figure 4. Belzona 1341 Supermetalglide applied.

Within the two-hour over coating window, the first coat of polymer (Belzona 1341 Supermetalglide) was applied by brush, followed by a second coat to obtain a total dry film thickness of 500 µ. This coating was specified because it protects against erosion and long-term corrosion of equipment, while providing a smooth surface to help improve pump efficiency.

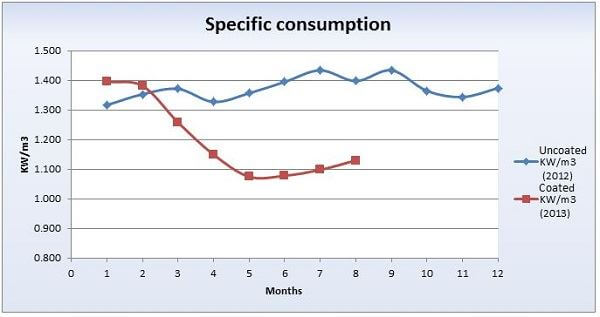

Graph 3. Energy consumption comparison.

Graph 3. Energy consumption comparison.

Graph 4. Power consumption KW/m3 depending on the flow.

Graph 4. Power consumption KW/m3 depending on the flow.

Results

The main results at the elevation plant in Portugal, after coating the pump and changing programming of the water elevation plan, were:

- Reduced energy consumption 12.5% during non-peak hours, from 44.9 to 39.3%

- Reduced energy consumption by 14.9% (kW/m3), 147,247 KW/h recorded in 8 months

- 20.3% cost reduction

- ROI: 4 months of maintenance-free operation

Similar results have been measured by many pump manufacturers around the world, and feedback on industrial equipment protected with these coating solutions show that it is possible to achieve a greater return performance than that of a new pump.