What Does

Compressive Strength Mean?

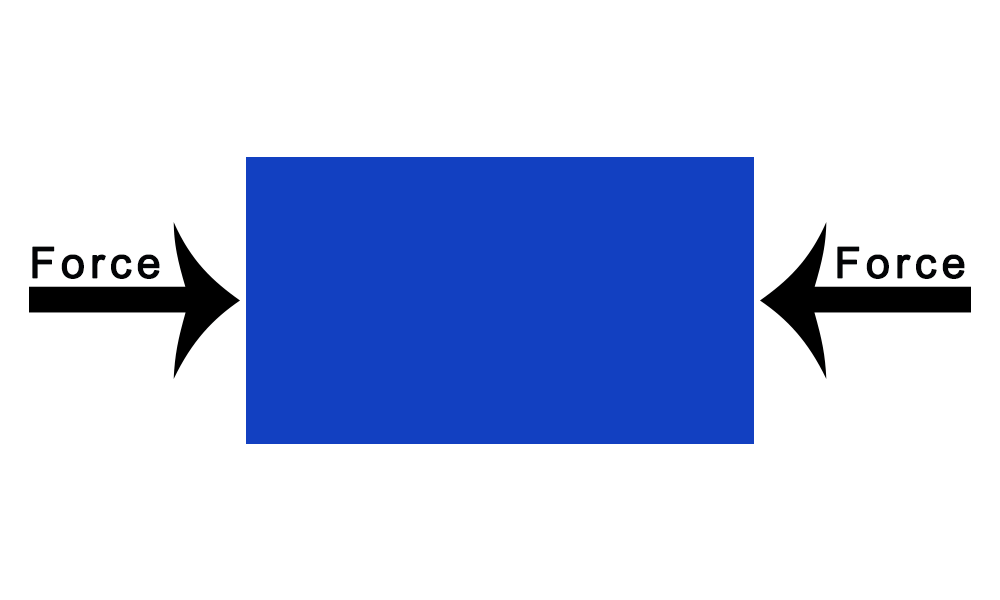

Compressive strength is the maximum compressive stress that, under a gradually applied load, a given solid material can sustain without fracture. The formula for calculating compressive strength is:

CS = F / A

Where in compressive strength (CS) is equal to the force (F) at the point of failure divided by the cross sectional area. Compressive strength tests must be performed with equal opposing forces on the test material. Test materials are normally in cylinders, cubes or spheres.

Some materials fracture at their compressive strength limit; others deform irreversibly. Compressive strength is a key value for designing structures. The compressive strength of concrete is the most common performance measurement used by engineers when designing buildings and other structures.

Corrosionpedia Explains Compressive Strength

Compressive strength is a limit state of compressive stress that leads to failure in a material in the manner of ductile failure (infinite theoretical yield) or brittle failure (rupture as the result of crack propagation, or sliding along a weak plane). Compressive strength is measured on materials, components and structures. By definition, the ultimate compressive strength of a material is that value of uniaxial compressive stress reached when the material fails completely.

Measurements of compressive strength are affected by the specific test methods and conditions of measurement. Compressive strengths are usually reported in relationship to a specific technical standard.

Concrete and ceramics typically have much higher compressive strengths than those with high tensile strengths. Composite materials, such as glass fiber epoxy matrix composite, tend to have higher tensile strengths than compressive strengths. Concrete is usually reinforced with materials that are strong in tension. Compressive strength is a widely used for specification requirements and quality control of concrete. Engineers know their target tensile (flexural) requirements, and express these in terms of compressive strength.

Concrete compressive strength requirements can vary from 2,500 psi for residential concrete to 4,000 psi and higher in commercial structures. Higher strengths up to and exceeding 10,000 psi are specified for certain applications.

For both ductile and brittle materials, the compressive strength is usually significantly higher than the tensile strength. Exceptions to this include fiber-reinforced composites such as fiberglass, which are strong in tension but are easily crushed. Concrete, however, which is a particle-reinforced composite, is far stronger in compression than tension to the extent that if it is going to be exposed to tensile forces, it needs to be reinforced with steel rods.