What Does

Pin-Holing Mean?

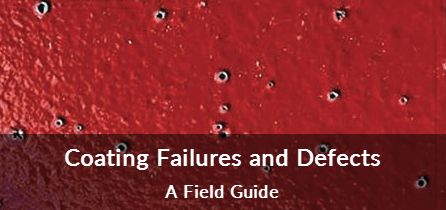

Pin-holing refers to a small, sunken area that forms on a coating film after a bubble ruptures. Pinholes are typically larger and less abundant across a coating’s surface than solvent pops.

They are tiny holes or groups of holes in the finish, or in putty or primer which are the result of:

- Trapped solvents

- Air

- Moisture

- Improper surface preparation

Pin-holing is also known as pin holes, solvent retents, pock marks, pitting, pops or pin pricks.

Free Coating Failures and Defects Guide – Sponsored by Fitz’s Atlas 2

Click here to download your free guide!

Corrosionpedia Explains Pin-Holing

Pin-holing are tiny holes in the finish caused by surface porosity or other imperfections in the substrate. It is an occurrence of small holes which provide a path of exposure to the substrate from improper spray atomization or segregation of the resin from the pigment in the coating. For example, in thin film epoxy coatings, excessive heat can cause similar effects by foaming the resin.

Origin & causes of pin-holing:

- Poor surface cleaning or preparation

- Contamination of air lines

- Wrong gun adjustment or technique

- Incorrect thinner or reducer

- Incorrect drying

- Insufficient sanding or filling of pores in fiberglass substrates

- Solvent popping that has not been sanded smooth

Coating applicators have several options for minimizing the formation of pinholes. They can inspect the surface and correct porosity or surface imperfections in the substrate before applying the topcoat. After thorough drying of the affected area, it must be sanded completely smooth, and undercoats reapplied as necessary and refinished depending on the system.