The blast pressure directly determines the velocity of the blast media through the blasting nozzle, and therefore the impact force on the substrate.

While there are a wide range of pressures that can accomplish the same job, choosing the optimal pressure for a specific application requires balance. Blast pressures that are set too low can drastically reduce the speed and efficiency of blast cleaning. On the other hand, pressures that are too high can shatter the abrasive media upon impact, resulting in reduced energy transfer and cleaning efficiency.

One of the most significant factors that determine the optimum blast pressure for a specific application is the type of material that needs to be removed. Lower pressures are adequate for the removal of thin coatings, dirt and grease, while higher blast pressures are necessary to remove sturdier materials such as rust and heavy coatings. Higher pressures may also be required to clean small and hard to reach areas.

Another factor to take into consideration is the profile depth or surface preparation standard that needs to be achieved (e.g., white metal, near white metal, etc.). For example, in instances where coatings or contaminants require removal without changing the surface profile of the substrate, excessively high pressures may not be appropriate. (Discover the 6 Ways to Measure Surface Profiles for Concrete Surface Preparation.) It is therefore essential that the required profile and the substrate material be analyzed beforehand to determine the most appropriate blast pressure.

Finally, the material to be cleaned must also be taken into consideration. Abrasive blast cleaning can potentially damage the substrate if the pressure is set too high. Wood, for example, needs to be cleaned at relatively lower pressures (when compared to steel) to avoid damage to the wood fibers.

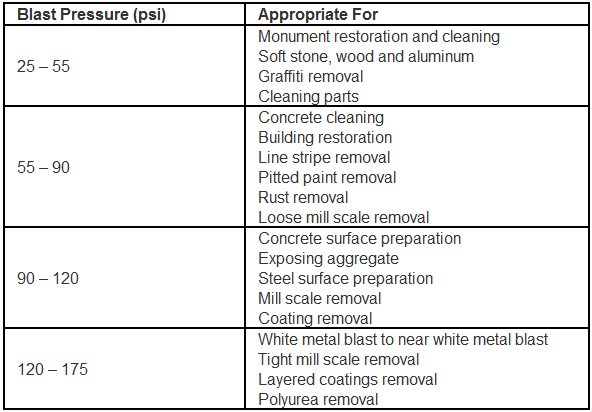

The table below gives some ballpark values for appropriate blast pressures for various materials and situations. It is only intended to be used as a guide; fine-tuning of the blast pressure in the field is recommended to ensure the desired results are achieved.