What Does

Blistering Mean?

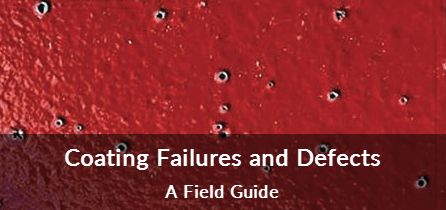

Blistering is the formation of small to large, broken or unbroken bubbles, which are under or within a coating at the paint/metal interface. Although blisters can form between layers of paint, these are less common. Blisters are often liquid filled and may take the form of clusters (or rashes).

Blistering causes adhesion failure and is catastrophic, therefore blistering causes damage to the structure or metal surface, which may incur substantial loss.

Blistering is the result of adhesion failure in localized areas. They can be any size and distribution. Numerous factors can lead to blistering, but the most common is a contaminant of some kind left on the surface after cleaning.

Free Coating Failures and Defects Guide – Sponsored by Fitz's Atlas 2

Click here to download your free guide!

Corrosionpedia Explains Blistering

There are several specific types of blistering, including:

- General blistering

- Intercoat blistering

- Non-osmotic blistering

- Osmotic blistering

Blistering is the formation of dome- or circular-shaped bubbles of the coating film held away from the substrate. Blisters can have irregular shapes, depending on the cause. They may be filled with:

- Water

- Solvent/caustic

- Gas/oxygen

- Crystals

- Rust

When adhesion is poor, blisters that form can remove the coating from the substrate, either isolated as blisters, or by total delamination of the coating. Isolated water-filled blisters are usually formed in softer coatings. Once formed, blisters can grow during continued water exposure, for example, by osmotic effects.

Common causes of blistering include:

- Poor surface preparation

- Poor wetting of substrate

- Improper solvent

- Oil or moisture contamination

- Salt contamination

- Excessive cathodic protection

To minimize blistering problems, a coating with very strong adhesion strength and low moisture vapor transfer rate should be used. A clean substrate with proper surface preparation and reduced soluble salt levels to suit service exposure are essential.

Blisters should not be broken unless it is to test them or their contents to determine cause. While they are abnormalities, blisters can still help protect the surface.